TM 55-1520-240-23-6

7-151

INSTALL UTILITY HYDRAULIC PUMP

(Continued)

7-151

NOTE

When installing a Stratopower/

Dynapower pump there is a metal

shim bonded to pump flange. If this

shim comes unbounded from the

pump flange. It does not have to be

rebounded for installation.

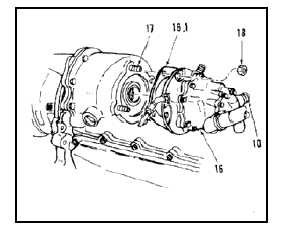

9.

Install gasket (16.1) on pump (16) and position

pump (16) on four studs (17), with IN port (10)

up. Wear gloves (E184.1).

Oil (E254 or E254.1) is toxic. They can

irritate skin and cause burns. Avoid

inhaling. Use only with adequate

ventilation. Avoid contact with skin,

eyes, or clothing. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

10.

Install four nuts (18). Torque nuts wet with oil

(E254 or E254.1) to 70 to 100 inch-pounds.

NOTE

Torque on nuts (18) must be checked

for 85 inch-pounds after the first

flight. Do not back off nuts before

torquing.

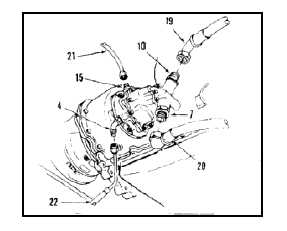

11.

Remove cap and connect hose (19) to IN port

(10).

12.

Remove cap and connect hose (20) to OUT port

(7).

13.

Remove cap and connect hose (21) to port (15).

14.

Remove cap and connect hose (22) to port (4).

15.

Use cloths (E135) for any spilled fluid. Wear

gloves (E184.1).

INSPECT

FOLLOW-ON MAINTENANCE:

Service hydraulic reservoir (Task 1-62).

Bleed utility hydraulic system (Task 7-336).

Perform utility hydraulic pump operational check (TM

55-1520-240-T).

Close right aft transmission access panel (Task 2-2).

Close cargo ramp (TM 55-1520-240-T).

END OF TASK

7-671