TM 55-1520-240-23-6

7-132

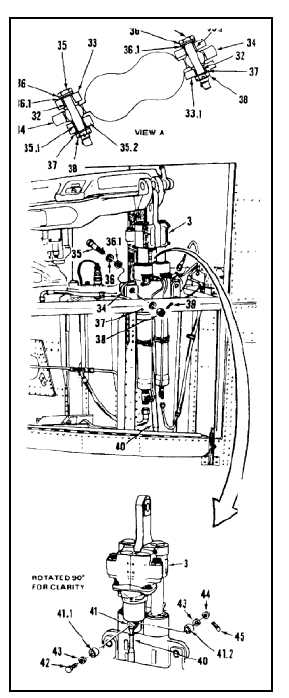

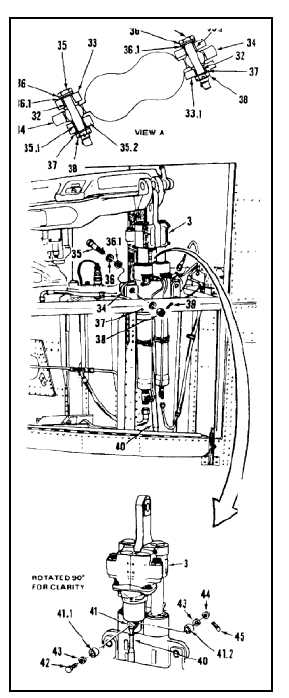

INSTALL AFT PIVOTING SERVOCYLINDER

(Continued)

7-132

Make sure bushings are installed in

lugs. Otherwise, personal injury, loss

of life, or loss of helicopter can result.

12.

Check that flanged bushings (32) are installed

in forward inboard lug (33) and aft outboard lug

(33.1).

13.

Have helper support cylinder (3). Position

cylinder mounts (34) between lugs (33 and 33.1).

NOTE

Two washers may be installed under

nut to allow for cotter pin installation.

Install countersunk washers with

countersink against bolthead.

13.1.

Install forward bolt (35) as follows:

a.

Insert slip fit bushing (35.1) in outboard lug

(35.2).

b.

Install countersunk washer (36) and washer

(36.1) on bolt (35).

c.

While holding bushing (35.1) in position,

install bolt (35). Install one or two washers

(37) and nut (38).

13.2.

Install aft bolt (35) as follows:

a.

Install countersunk washer (36), washer

(36.1), and slip fit bushing (35.1) on bolt (35).

b.

Install bolt (35). Install one or two washers

(37) and nut (38).

14.

Torque nuts (38) to 290 to 660 inch-pounds.

Install cotter pins (39).

15.

Install inner bushing (41.1) and outer bushing

(41.2). Position link (40) in lugs (41). Install bolt

(42) with one washer (43) through bushings and

lugs, one washer (43), and nut (44).

16.

Torque nut (44) to 30 to 45 inch-pounds. Install

cotter pin (45).

17.

Check bolt (42). Bolt shall not rotate with torque

less than 10 inch-pounds. There shall be no

axial looseness. If bolt rotates, or is loose, add

washer under nut. Torque and cotter pin nut

again.

7-596