TM 55-1520-240-23-6

7-326

FLUSH CARGO DOOR MOTOR TUBING

(Continued)

7-326

Filter assembly kit

ADHT6814-M9716M must be

installed in test stand pressure

line. Otherwise, system can be

contaminated.

NOTE

To operate hydraulic test, stand refer

to applicable manual.

1.

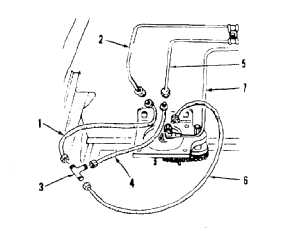

Working through cargo ramp panel, connect

hose (1) to tube (2) and tee (3).

2.

Connect hose (4) to tube (5) and tee (3).

3.

Connect hose (6) to tube (7) and tee (3).

4.

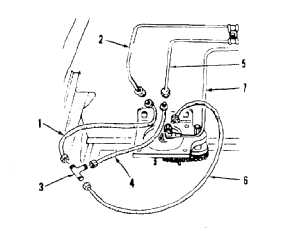

Working from ramp forward right side, tag and

disconnect three hoses (8, 9, and 10) from

elbows (11, 12, and 13).

5.

Connect test stand pressure hose (14) to elbow

(11).

6.

Connect hose (15) to elbow (12) and tee (16).

7.

Connect hose (17) to elbow (13) and tee (16).

8.

Connect test stand return hose (18) to tee (16).

Do not exceed 500 psi. Otherwise

damage to components can occur.

Keep test stand bypass valve closed.

Otherwise, contaminants could

re-enter the system.

9.

Apply hydraulic power. Set stand to 10 gpm at

500 psi. Flush system for 15 minutes. Check

for leaks.

10.

Move hydraulic power.

11.

Disconnect hose (18) from tee (16). Use cloths

(E120) and container for spilled fluid.

12.

Remove two hoses (15 and 17) from tee (16)

and elbows (12 and 13).

13.

Remove hose (14) from elbow (11). Use cloths

(E120) and container for spilled fluid. Use gloves

(E186).

14.

Connect UP RAMP hose (10) to elbow (13).

Remove tag.

15.

Connect DOWN RAMP hose (9) to elbow (12).

Remove tag.

16.

Connect RETURN hose (8) to elbow (11).

Remove tag.

INSPECT

7-1195