TM 55-1520-240-23-6

7-280

TEST CARGO DOOR SEQUENCE VALVE (AVIM)

(Continued)

7-280

17.

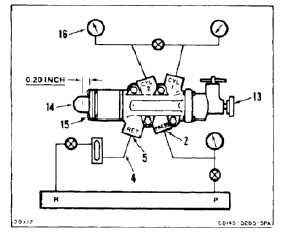

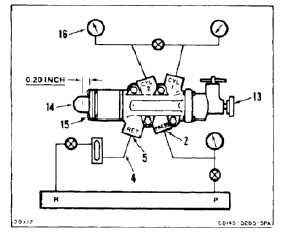

Connect hose (4) to RET port (5).

18.

Mark cartridge (14) 0.20 inch from housing (15).

Use marking pencil (E271).

19.

Push in and hold cartridge (14) until mark on

cartridge aligns with housing (15).

20.

Push in MANUAL OPER knob (13).

21.

Apply 3000 psi pressure to PRESS port (2).

Maintain pressure for 3 minutes. When 2

minutes have passed, check RET port (5) for

leaks. Leaks from RET port shall not exceed 20

drops per minute after 2 minutes.

22.

Check pressure reading at gage (16). Pressure

reading shall be 3000 psi.

23.

Release cartridge (14).

24.

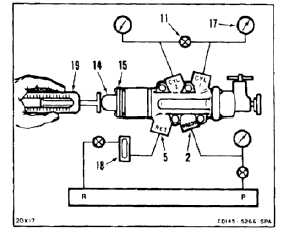

Check pressure at gage (17). Pressure shall be

3000 psi.

25.

Open shutoff valve (11) slowly until flowmeter

(18) shows 1 gpm flow from RET port (5).

26.

Release MANUAL OPER knob (13).

27.

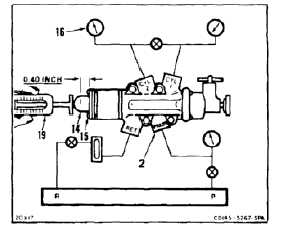

Apply force against cartridge (14) until it starts

to move. Use reverse spring scale (19). Check

force to move cartridge. Force shall be 9 to 15

pounds.

28.

Align mark on cartridge (14) with housing (15).

Use reverse spring scale (19). Check force

needed to align mark on cartridge with housing.

Force shall not exceed 22 pounds.

29.

Check pressure at gage (16). Pressure shall be

3000 psi.

30.

Push cartridge (14) into housing (15) past

alignment mark. Use reverse spring scale (19).

Check force needed to push cartridge past

alignment mark. Force shall be 25 pounds or

more.

31.

Release cartridge (14).

32.

Remove alignment mark from cartridge (14).

33.

Reduce pressure at PRESS port (2) to 0 psi.

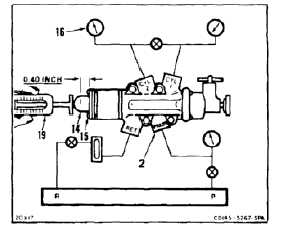

34.

Mark cartridge (14) 0.40 inch from housing (15).

Use marking pencil (E271).

7-1042