TM 55-1520-240-23-5

6-217

VIBRATION CORRECTION PROCEDURE (AVIATION VIBRATION

ANALYZER) (Continued)

6-217

10.

Repeat step 4. If check is still unsatisfactory,

continue with step 11.

11.

Perform engine drive shaft vibration check

with No. 1 engine at minimum beep and rpm

re-established at 100 percent with No. 2 engine

only.

12.

Repeat the check of step 11 with No. 2 engine

at minimum beep and rpm re-established at 100

percent with No. 1 engine only.

13.

Shut down engines (TM 1-1520-240-10).

NOTE

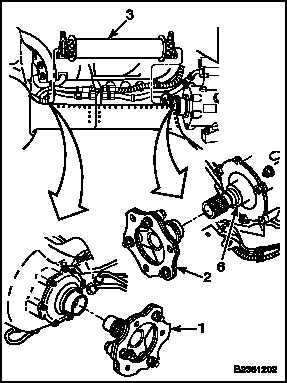

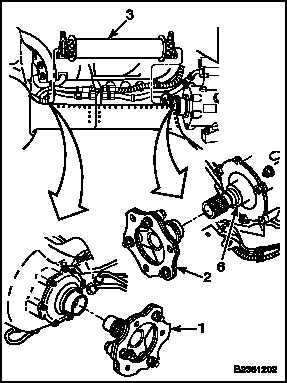

No. 2 engine drive shaft is shown.

No. 1 shaft is similar.

14.

Compare vibration readings of steps 11 and 12.

If readings of step 12 are higher, perform steps a

thru d on No. 2 engine drive shaft (3). If readings

of step 11 are higher, perform steps a thru d on

No. 1 shaft.

a.

Match-mark adapters (1 and 2) to shaft (3).

Use a marking pencil (E270.1).

b.

Remove shaft (3) (Task 6-30).

c.

Remove adapter (2) from combining

transmission (6) (Task 6-30). Rotate it 90

clockwise facing combining transmission

input pinion and reinstall it (Task 6-32).

d.

Align match-marks on adapters (1 and 2) and

shaft (3). Reinstall the shaft (Task 6-32).

15.

Repeat step 6. If check is still unsatisfactory,

repeat steps 11 thru 14 a maximum of two

times. If vibration still exceeds 1.0 ips, replace

the fan (Tasks 6-182 and 6-186).

NOTE

If fan has been replaced, repeat entire

vibration analysis.

6-710

Change 1