TM 55-1520-240-23-5

6-217

VIBRATION CORRECTION PROCEDURE (AVIATION VIBRATION

ANALYZER) (Continued)

6-217

ENGINE DRIVE SHAFTS

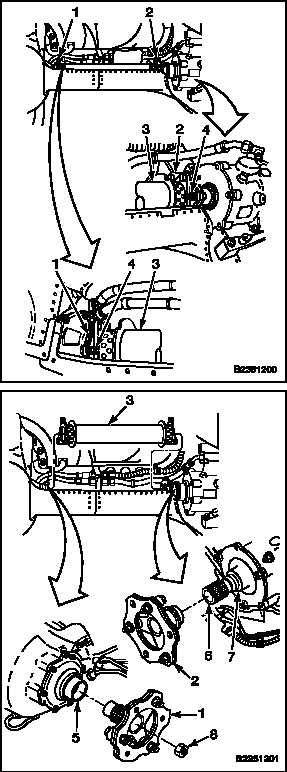

NOTE

Adjust No. 1 and No. 2 engine drive

shaft in the same way. No. 2 engine

drive shaft shown.

1.

Inspect adapter assemblies (1 and 2) at each

end of shaft (3) (Task 6-30.1).

2.

Loosen nuts (4) at adapter assemblies (1 and 2)

of shaft (3). Hold bolt heads to keep bolts from

turning.

CAUTION

If bolts are allowed to turn, bolts,

plates and shaft adapter assembly

can be damaged.

3.

Torque nuts (4) to 440 inch-pounds.

4.

Perform a vibration check for engine drive

shafts. If vibration is not greater than 1.0 ips,

go to Follow-On Maintenance. If check is

unsatisfactory (vibration greater than 1.0 ips),

continue with step 5.

5.

Match-mark each drive shaft (3) to adapters

(1 and 2). Match-mark adapter (1) to engine

transmission (5) and adapter (2) to combining

transmission (6). Use a marking pencil (E270.1).

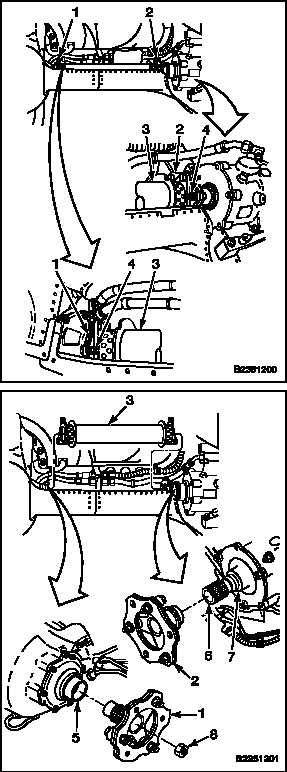

6.

Remove drive shaft (3) and adapters (1 and 2)

(Task 6-30). Inspect shaft and adapters (Task

6-30.2). Check interior of shaft for water and

foreign objects.

WARNING

Dry cleaning solvent (E162) is

combustible and toxic. It can irritate

skin and cause burns. Use only with

adequate ventilation, away from open

flame. In case of contact, immediately

flush skin or eyes with water for

at least 15 minutes. Get medical

attention for eyes.

7.

Clean splines on adapters (1 and 2), splines (7)

on combining transmission (6), thread of nut (8),

and mating stud within engine transmission (5).

Use solvent (E162) and cloths (E120). Wear

gloves (E184.1).

8.

Inspect all splines for wear or damage.

9.

Install adapters (1 and 2) and drive shaft (3)

(Task 6-32). Make sure all match-marks line up.

Change 1

6-709