TM 55-1520-240-23-5

6-50

ASSEMBLE FORWARD TRANSMISSION PACKAGE

(Continued)

6-50

Using standard bolts could result in

bolt failure. Damage to parts can

result.

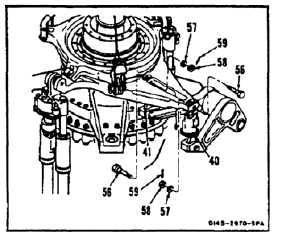

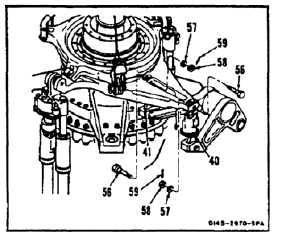

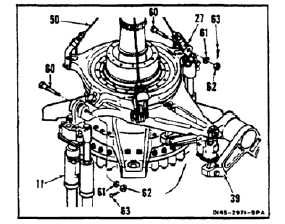

28.

Coat bushing of special bolts (56) with antiseize

compound (E75). Do not coat thread.

29.

Install two special bolts (56), with heads away

from each other, washers (57), and nuts (58)

through upper ends of actuator (40) and link (41).

Torque the nuts to 400 to 660 inch-pounds.

Install cotter pin (59). Add a thin washer under

the nut if needed to install the cotter pin.

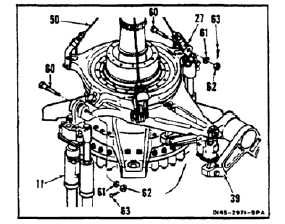

30.

Coat bushing of special bolts (60) with antisieze

compound (E75). Do not coat thread.

31.

Install two special bolts (60), heads away

from yoke (39), washers (61), and nuts (62) in

servocylinders (11 and 27). Torque the nuts to

400 to 600 inch-pounds. Install cotter pin (63).

Add a thin washer under the nut if needed to

install the cotter pin.

32.

Remove sling (T14) (50).

Oil (E253, E254, or E254.1) is

toxic. It can irritate skin and cause

burns. Avoid inhaling. Use only with

adequate ventilation. Avoid contact

with skin, eyes, or clothing. In case

of contact, immediately flush skin

or eyes with water for at least 15

minutes. Get medical attention for

eyes.

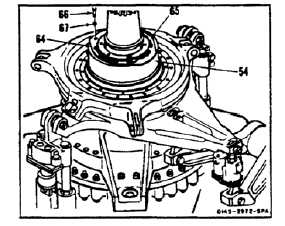

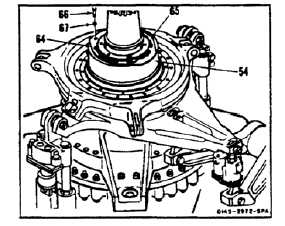

33.

Position seal halves (64 and 65) on shaft (54).

Apply a light coat of oil (E253, E254, or E254.1)

to the thread of 12 bolts (66). Install the bolts and

washers (67). Ensure that a minimum clearance

of 0.050 inch exists between the rubber seal

and the surface of the rotor shaft. If a minimum

clearance does not exist, move seal (64 or 65)

radially as far away from the shaft as possible

and recheck clearance. Torque the bolts to 60

inch-pounds.

34.

Lockwire six bolts (66) on each half of seal (64)

in two groups of three bolts each. Use lockwire

(E231).

6-187