TM 55-1520-240-23-4

5-112

INSTALL DRIVE ARMS

(Continued)

5-112

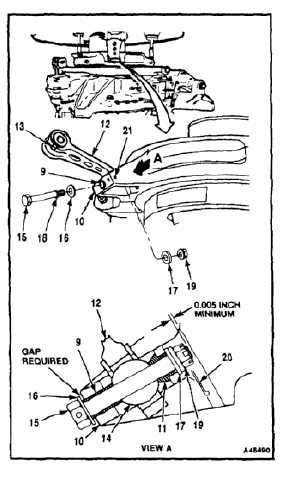

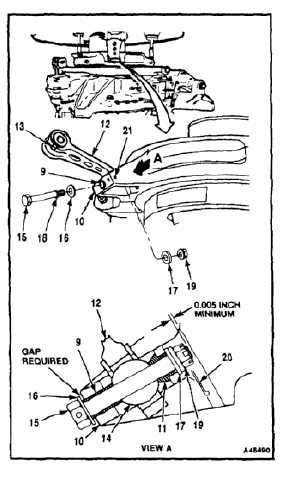

CONNECT LOWER DRIVE ARM TO SWASHPLATE

If bushing (9) is not installed in

swashplate lug (10), personal injury or

loss of life could occur.

NOTE

At the forward swashplate, make sure

lower drive arm is installed in lug

marked FWD. At the aft swashplate,

make sure lower drive arm is installed

in lug marked AFT. Installation at a

forward swashplate is shown here.

9.

Remove the retaining strap from bushing (9) in

swashplate lug (10). If a new swashplate has

been installed, check that a bushing (9) is in

lug (10). Check for the presence of shouldered

bushing (11). Position lower drive arm (12), with

mechanical stop (13) outboard, in the swashplate

lug. Align bearing (14) with bushings (9 and 11).

10.

Install bolt (15), with thin, smaller-inside diameter

washer (16) under the head, and larger-inside

diameter washer (17) over retaining ring (18).

With the bolt fully inserted, check that the

retaining ring protrudes past washer (17) and

is free to turn.

11.

Install nut (19). While holding the nut, torque bolt

(15) to 190 inch-pounds. Continue tightening

the bolt as needed to align cotter pin holes in the

nut and bolt. Do not exceed 270 inch-pounds.

12.

Check for clearance between the threaded end

of bolt (15) and the inside face of the swashplate,

as shown. Clearance shall be at least 0.005

inch. Add a thin or thick washer under the bolt

head if needed. Install cotter pin (20).

13.

Check that there is a gap between washer (16)

and lug (10) as shown.

14.

Apply a torque of 65 inch-pounds to the head of

bolt (15). The bolt shall not turn.

15.

Lockwire bolt (15) to hole (21) in lug (10). Use

lockwire (E231).

INSPECT

5-637