TM 55-1520-240-23-4

5-72.1

REPLACE BLADE FAIRING TIP SECTION

(Continued)

5-72.1

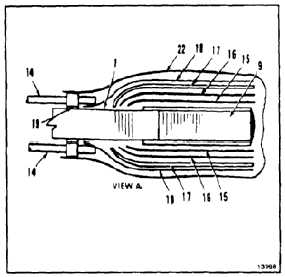

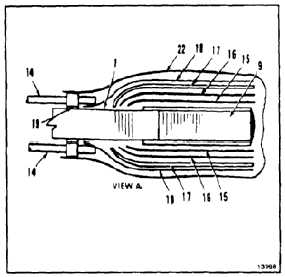

j.

Start vacuum pump. Check for leaks.

Reposition bag (22) or add tape (E396) (19)

as needed.

k.

Maintain 20 inches Hg vacuum through

adhesive cure.

Do not exceed 160ºF (71ºC) at blade

surface. Damage to fiberglass can

occur.

l.

Cure adhesive at 140º - 160ºF (60º - 71ºC)

for 2 hours. Use heat lamp. Monitor

temperature. Use temperature indicating

strips (E413). Vacuum may be removed after

12 hours.

NOTE

Serviceable cure can be achieved

without heat at 70º - 80ºF (21º - 27ºC)

in 24 hours.

m.

Turnoff vacuum pump.

n.

Remove bag (22), tube (14), tape (19),

fiberglass (18), rubber (17), fabric (16), and

peel ply (15).

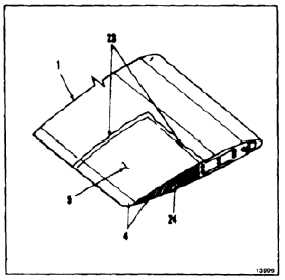

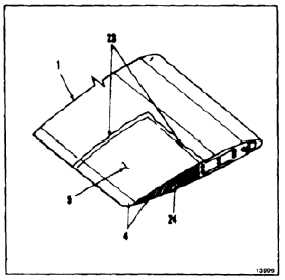

25.

If squeezeout fairing (23) is not satisfactory, fair

doubler (4) and mesh (5) to surface of blade (1)

with adhesive (E40 or E41). Prepare adhesive

mixture as in steps 9 and 10.

26.

Refinish tip seal area (24) (Task 5-76 or 5-77).

27.

Add recorded weights of doublers (4), mesh (5)

and adhesive used.

NOTE

All blade repairs, weight adjustment,

painting, or balancing will be recorded

on rotor blade DA Form 2408-16,

each blade requires a separate form.

If the rotor blade does not have a DA

Form 2408-16, one must be prepared

and all actions recorded, as example;

location of repair, size of repair,

weight of repair, and required weight

adjustments for track and balance.

FOLLOW-ON MAINTENANCE:

Refinish repaired area (Task 5-82).

Adjust balance weights (Task 5-82.1).

END OF TASK

5-418