TM 55-1520-240-23-3

4-13

INSTALL POWERPLANT (Continued)

4-13

CAUTION

Make sure powerplant weight is on aft

support link and not on firewall former.

Damage to powerplant and former

can occur if weight is not on support

link.

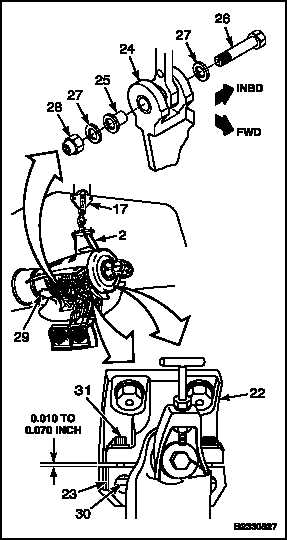

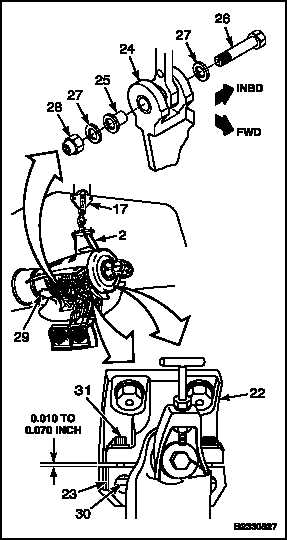

9.

Install slip fit bushing (25), shoulder outboard,

in clevis (24).

10.

Install bolt (26), two washers (27), and nut (28).

Raise or lower powerplant (2) as needed for

clearance.

11.

Adjust firewall former (29) (Task 4-44).

12.

Relax tension on hoist (17).

13.

Torque nut (28) to 350-400 inch-pounds to

seat bushing. Loosen nut and retorque to 20

inch-pounds above run-on torque. Not to be

less than 70 inch-pounds.

INSPECT

14.

Check barrel nuts (30). Breakaway torque shall

not be less than 7 inch-pounds.

15.

Push four bolts (31) up and over adapter (22)

and tighten evenly.

16.

Torque bolts (31) to 20 inch-pounds above

friction torque.

NOTE

It is acceptable for clearances to vary

inboard to outboard and/or forward

to aft providing the clearance at any

point is within the defined limits.

17.

Measure gap between adapters (22) and caps

(23). Gap shall measure 0.010 to 0.070 inch.

18.

Torque bolts (31) to 105 inch-pounds.

19.

Measure gap between adapters (22) and caps

(23). Gap shall measure 0.010 to 0.070 inch.

NOTE

It is acceptable for clearances to vary

inboard to outboard and/or forward

to aft providing the clearance at any

point is within the defined limits.

20.

Check bolts (31). Bolts shall protrude a minimum

of two threads through barrel nuts (30), but shall

not bottom out. Add washers under bolthead

if bolt is bottoming out. Lockwire bolts. Use

lockwire (E231).

Change 1

4-111