TM 55-1520-240-23-9

11-243

INSTALL TUNNEL CONTROLS IDLER

(Continued)

11-243

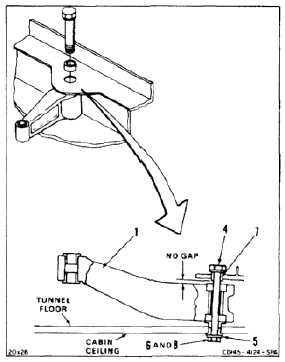

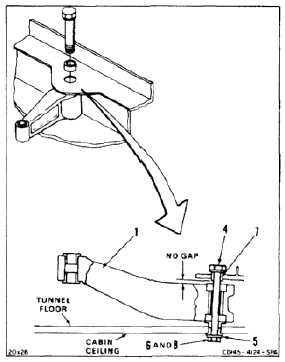

6.

Check idler (1) for up and down play. Check for

gap between bushing (7) and idler (1). There

shall be no gap. If there is play or gap, adjust

idler as follows:

Do not use shear nut to pull bushing

into contact with idler bearing. Nut

can strip and damage bolt.

a.

Remove shear nut (6).

b.

Install tension nut (8).

Do not damage or bend structure

while seating bushing.

c.

Torque nut (8) to seat bushing (7) on idler

bearing. Do not exceed 170 inch-pounds.

Do not strike bolthead with strong

force. Damage to structure can result.

d.

If necessary, carefully tap head of bolt (4) to

seat bushing (7) on bearing.

e.

Install new bolt (4), new nut (6), and

new washer (5). Torque nut to 60 to 90

inch-pounds.

7.

Check tunnel control idler (1) for binding. If there

is no binding go to step 8. If there is binding

replace idler. There shall be no binding.

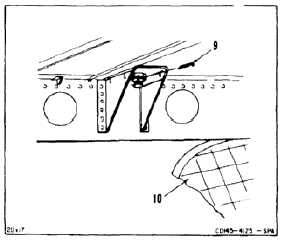

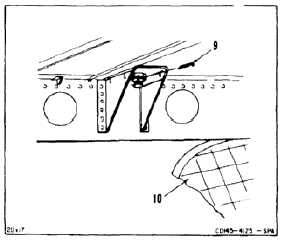

8.

Install cotter pin (9).

9.

Push edge of insulation blanket (10) back into

place (Task 2-210).

11-946