TM 55-1520-240-23-9

11-214

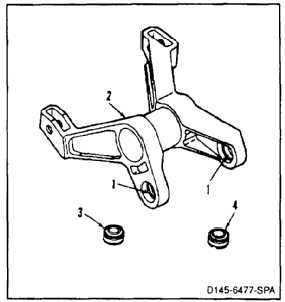

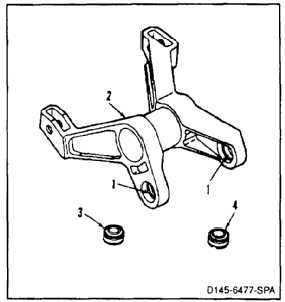

INSTALL FORWARD LCT YOKE BEARINGS

(Continued)

11-214

Do not use cadmium plated hardware

or tools while working on yoke

assembly. Titanium yoke could be

damaged.

NOTE

If a crack in the yoke is suspected

during removal, refer to TM

1-1520-253-23.

1.

Make sure bores (1) of yoke (2) are clean and

undamaged.

2.

Place both bearings (3 and 4) in carbon dioxide

(dry ice) (E92) and methanol (E243). Wear

goggles and Kevlar gloves (E187). Allow

bearings to cool thoroughly.

3.

Coat bores (1) with epoxy primer (E292). Wear

gloves (E184.1).

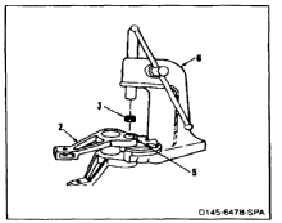

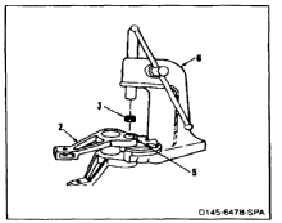

4.

Support bearing housing (5) of yoke (2) in arbor

press (6).

NOTE

Work quickly with chilled bearing.

Bearing must be installed before it

warms.

5.

Remove one bearing (3) from dry ice and wipe

clean and dry. Use cloth (E120). Wear goggles.

Wear Kevlar gloves (E187).

6.

While epoxy primer (E292) is wet press bearing

(3) into housing (5) until fully seated in bore (1)

(TM 55-1500-322-24). Use arbor press (6).

7.

Wipe off excess primer from bearing (3). Use

cloth (E120). Allow bearing to warm to room

temperature.

11-846