TM 55-1520-240-23-9

11-167

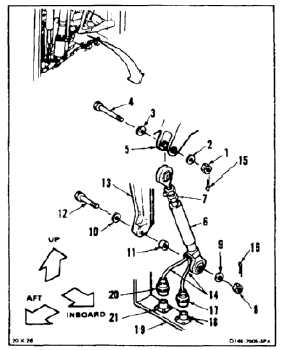

INSTALL YAW POSITION TRANSDUCER

(Continued)

11-167

Bushings must be in bellcrank

and support before installing bolts;

otherwise, damage to components

will result.

NOTE

Impedance bolts are installed in flight

control connections. These bolts are

self-retaining and require a special

nut and torque (Task 1-13).

1.

Remove nut (1), two washers (2 and 3), and bolt

(4) from bellcrank (5).

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured.

After electrical nulling procedure is

accomplished, ensure adjustable rod

end bearing assembly is properly

saftied by torquing jam nut against

locking tab washer assembly per

BAC5009, and installing safety wire

between jam nut and locking tab

washer assy per BAC5018.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

secondary linkage will degrade

aircraft control. Missing components

will cause loss of control.

2.

Position yaw linear transducer (6), adjustable

end (7) up, in bellcrank (5). Install bolt (4), two

washers (3 and 2), and nut (1). Do not tighten

nut at this time.

3.

Remove nut (8), two washers (9 and 10), spacer

(11), and bolt (12) from support (13).

4.

Position transducer (6), wires (14) aft, on support

(13) with spacer (11) between transducer and

support. Install bolt (12), two washers (10 and

9), spacer (11) between support and transducer,

and nut (8).

5.

Torque two nuts (1 and 8) to 30 to 45

inch-pounds. Install two cotter pins (15 and 16).

6.

Check two bolts (4 and 12). Bolts shall not rotate

with torque less than 10 inch-pounds. There

shall be no axial looseness. If bolt rotates or is

loose, add washer under nut and repeat step 5.

Connectors must be installed in fully

locked position; otherwise, component

malfunction can result.

7.

Connect connector (17) of wire with green band

of transducer (6) to inboard receptacle (18) on

structure (19). Remove tag.

8.

Connect connector (20) of wire with red band of

transducer (6) to outboard receptacle (21) on

structure (19). Remove tag.

FOLLOW-ON MAINTENANCE:

Perform yaw linear transducer adjustment check

(Task 11-176).

Perform operational test of advanced flight control

system (TM 55-1520-240-T).

Install closet backup panel (Task 2-2).

Install closet acoustic blanket (Task 2-108).

END OF TASK

11-683