TM 55-1520-240-23-9

11-164

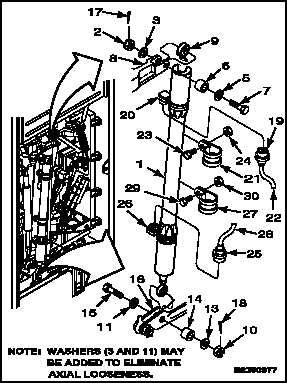

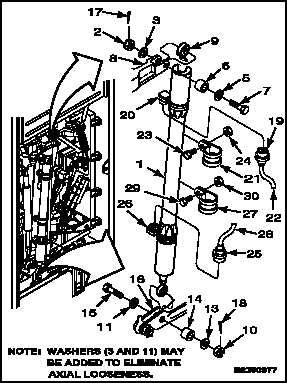

INSTALL DASH ACTUATOR (Continued)

11-164

CAUTION

Bushing must be in bellcranks before

installing bolt; otherwise, damage to

component will result.

NOTE

Impedance bolts are installed in flight

control connections. These bolts are

self-retaining and require a special

nut and torque (Task 1-13).

Prior to installation verify dimension

of upper rod end bearing and check

tightness of rod end checknut.

(Reference Task 11-163.4.)

NOTE

If a crack in the bellcrank is suspected,

refer to TM 1-1520-253-23.

1.

If DASH actuator (1) is a replacement, perform

adjustment check (Task 11-163.2).

2.

Remove nut (2), two washers (3 and 5), bushing

(6), and bolt (7) from upper bellcrank (8).

WARNING

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured at

each joint connection.

Ensure actuator is installed with

adjustable rod end up.

Ensure actuator is installed at

retracted length of 35.58 to 35.64

inches.

Ensure proper attaching hardware

(self retaining type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

NOTE

Washers (3) may be added to

eliminate axial looseness.

3.

Position actuator (1), small bearing (9) up and

AFCS connector (20) outboard in bellcrank (8).

Install bolt (7), two washers (5 and 3), bushing

(6), and nut (2). Do not torque nut at this time.

4.

Remove nut (10), two washer (11 and 13),

bushing (14), and bolt (15) from lower bellcrank

(16).

NOTE

Washers (11) may be added to

eliminate axial looseness.

5.

Position actuator (1), AFCS connector (26)

facing outboard in bellcrank (16). Install bolt (15)

bolt head facing outboard, washer (11) under

bolt head, bushing (14) between bellcrank (16)

washer (13) and nut (10).

6.

Torque two nuts (2 and 10) to 30 inch-pounds. If

necessary, continue tightening to align cotter pin

holes. Do not exceed 45 inch-pounds. Install

cotter pins (17 and 18).

Change 1

11-673