TM 55-1520-240-23-9

11-116

DISASSEMBLE, INSPECT AND REPAIR ROLL VISCOUS DAMPER (1025-820)

(AVIM)

(Continued)

11-116

Do not tear diaphragm; otherwise,

damper will malfunction.

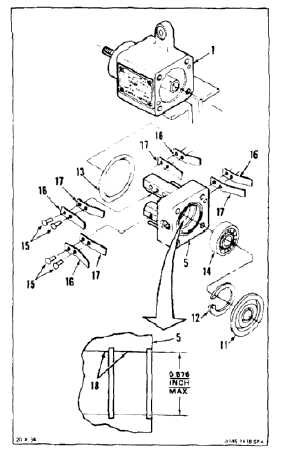

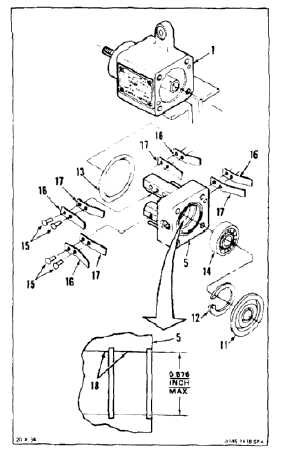

6.

Lift diaphragm (11) outer edge. Remove

diaphragm from abutment (5).

7.

Inspect diaphragm (11) for damage. There shall

be no cracks, tears or nicks.

8.

Remove retaining ring (12) from abutment (5).

Use retaining ring pliers.

9.

Pull abutment (5) outward. Remove abutment

from case (1).

10.

Remove packing (13) from abutment (5).

11.

Remove bearing (14) from abutment (5). Use

arbor press.

12.

Inspect bearing (14) (TM 55-1500-322-24).

Use care inspecting valve stops and

check valves. Damage to stops

or valves can cause component

malfunction.

13.

Inspect rivets (15), valve stops (16), and check

valves (17) for damage. There shall be no

looseness, distortion, or cracks. If damaged,

perform step 14. If not, go to step 15.

14.

Remove four rivets (15), four valve stops (16),

and four check valves (17) from abutment (5).

INSPECT

15.

Inspect bearing bore (18) of abutment (5). Blend

out damaged areas by burnishing or sanding.

Use crocus cloth (E123). Bore shall be 0.876

inch dia maximum.

11-551