TM 55-1520-240-23-9

11-115

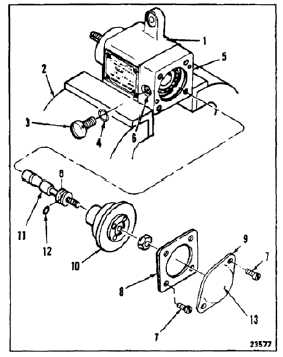

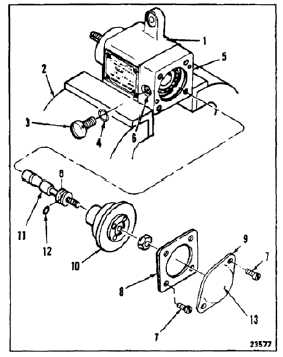

DISASSEMBLE, INSPECT AND REPAIR THRUST, PITCH OR YAW VISCOUS DAMPER

(1025-930 OR 1025-940) (AVIM)

(Continued)

11-115

NOTE

This task must be performed in a

clean area. Dirt on parts can cause

component malfunction.

General inspection criteria apply

unless otherwise stated (Task 1-92).

The thrust, pitch or yaw viscous

dampers are temperature

compensated.

Inspection steps cover parts that are

subject to wear.

1.

Install damper case (1) in vise (2).

2.

Remove lockwire from screw (3). Remove screw

and packing (4) from abutment (5).

3.

Remove case (1) from vise (2). Drain damping

fluid through port (6). Use container and cloths

(E120) for spilled fluid.

4.

Install case (1) in vise (2).

5.

Remove lockwire from four screws (7). Remove

screws, cover (8), and end cover (9) from

abutment (5).

NOTE

Do not tear diaphragm; otherwise,

damper will malfunction.

6.

Lift diaphragm (10) outer edge. Remove

diaphragm and valve assembly (11) from

abutment (5).

7.

Remove valve (11) from diaphragm (10) and

packing (12) from valve assembly (11).

8.

Inspect diaphragm (10) for damage. There shall

be no cracks, tears, or nicks. Check retainer is

bonded to diaphragm. Gently pull diaphragm at

90º to retainer.

9.

Check vent hole (13) in cover (9) is open.

11-546