TM 55-1520-240-23-6

7-102

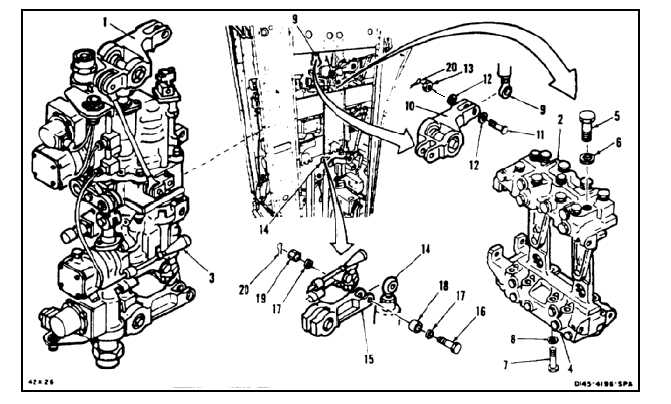

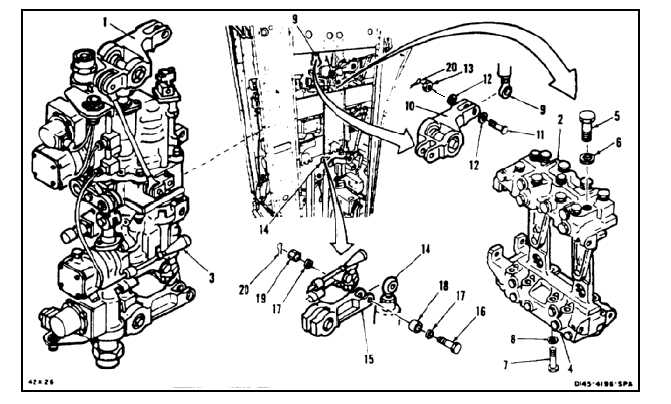

INSTALL INTEGRATED LOWER CONTROL ACTUATOR (ILCA)

(Continued)

7-102

NOTE

Procedure is same to install any

integrated lower control actuator

(ILCA) except where noted in text.

Installation of pitch actuator is shown

here.

There are no electrical connectors on

thrust actuator.

1.

Have helper support actuator (1). Position

actuator on manifold (2). Align tube (3) with port

(4).

NOTE

There are four bolts installed in

actuator. Two on top and two on

bottom. Top bolts are longer.

2.

Install two bolts (5) and washers (6).

3.

Install two bolts (7) and washers (8).

4.

Torque bolts (5 and 7) to 60 inch-pounds.

5.

Lockwire bolts (5 and 7) in pairs. Use lockwire

(E231).

6.

Position rod end (9) in lever (10). Install bolt (11),

two washers (12), and nut (13).

7.

Position rod (14) in lever (15). On pitch actuator

(1), install bolt (16), two washers (17), bushing

(18), and nut (19). On roll, yaw, and thrust

actuator (1), install bolt, three washers, nut, and

cotter pin.

8.

Torque nuts (13 and 19) to 30 to 60 inch-pounds.

9.

Install cotter pin (20) in nuts (13 and 19).

10.

Check bolts (11 and 16). Bolts shall not rotate

with torque less than 10 inch-pounds. There

shall be no axial looseness. If bolts rotate or are

loose, add washer under nut (13 and 19) and

repeat steps 8 and 9.

INSPECT

7-486