TM 55-1520-240-23-6

7-4.2

TUBE BENDING (AVIM)

(Continued)

7-4.2

16.

Check bends in tube (1) with micrometer as

follows:

a.

Measure and record maximum outside

diameter (OD).

b.

Measure and record minimum OD.

NOTE

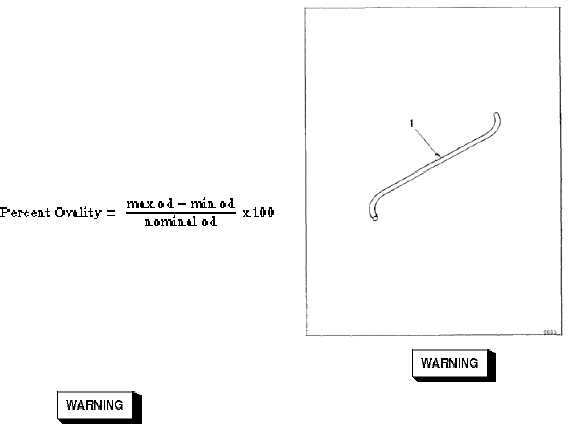

Operations of steps c, d, and e can be

expressed as follows:

(

)

c.

Subtract OD of step 16b from OD of step 16a.

d.

Divide result found in step 16c by average

(nominal) OD of tube (1).

e.

Multiply result found in step 16d by 100.

f.

Result found in step 16e is percent of ovality.

17.

Acceptable level of tube ovality or flatness shall

be 5 percent maximum.

Solvent (E161) is combustible and

toxic. It can irritate skin and cause

burns. Use only with adequate

ventilation, away from open flame. In

case of contact, immediately flush

skin or eyes with water for at least

15 minutes. Get medical attention

for eyes.

18.

Clean tube (1). Use solvent (E161).

Propelled debris can cause injury to

eyes. Use source of compressed air

under 30 psi and eye protection to

prevent injury to personnel.

19.

Dry tube (1) with low pressure compressed air.

Wear goggles to protect eyes.

20.

Inspect tube (1). There shall be no wrinkles

or kinks deeper than 1 percent of nominal

OD. There shall be no scratches deeper than

5 percent.

FOLLOW-ON MAINTENANCE:

Install end fittings and sleeves as required (Task 7-5).

Apply appropriate identification markings (APP E-50).

END OF TASK

7-26