TM 55-1520-240-23-6

7-334

BLEED UTILITY HYDRAULIC NO. 1 OR NO. 2 PTU MOTOR AND PUMP

(Continued)

7-334

Filter assembly kit

ADHT6814-M9716M must be

installed in test stand pressure

lines. Otherwise, system can be

contaminated.

NOTE

To operate hydraulic test stand, refer

to applicable manual.

NOTE

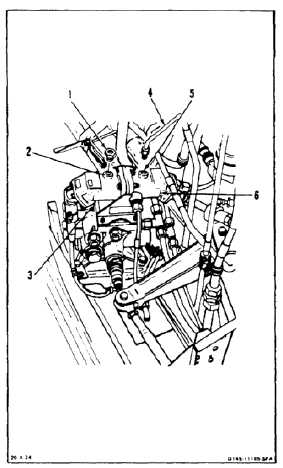

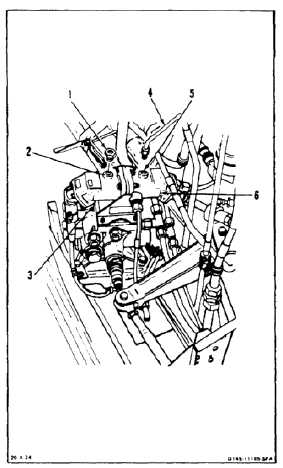

Procedure is same to bleed No. 1 or

No. 2 PTU motor and pump. No. 1

motor and pump is shown here.

1.

Remove plug (1) from port (2) of No. 1 PTU

motor (3).

2.

Fill pump (3) through port (2) with fluid (E199).

Use cloths (E120) for spilled fluid.

3.

Install plug (1) in port (2).

4.

Disconnect drain tube (4) from port (5) of pump

(6).

5.

Fill motor (6) through port (5) with fluid (E199).

Use cloths (E120) for spilled fluid. Use gloves

(E186).

6.

Connect tube (4) to port (5).

7.

Apply hydraulic power to flight system . Set test

stand to 300 psi.

8.

Apply hydraulic power to utility system. Slowly

increase pressure until motor (3) rotates. Have

helper on forward right work platform listen for

motor rotation. Allow pump to rotate for about 3

minutes.

9.

Remove hydraulic power from flight and utility

systems.

FOLLOW-ON MAINTENANCE:

Set POWER XFER NO. 1 switch on hydraulic panel

to OFF.

Disconnect hydraulic test stands from ground service

panel (Task 1-38).

Remove electrical power (Task 1-37).

Close right forward work platform or pylon right

access door (Task 2-2).

END OF TASK

7-1230