TM 55-1520-240-23-5

6-16

ASSEMBLE DRIVE SHAFT (Continued)

6-16

10.

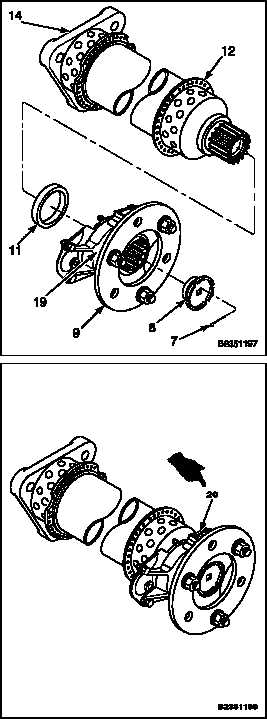

Install spacer (11) on adapter assembly (9).

NOTE

If adapter assembly and shaft

assembly does not have the same

serial number, they must be returned

to depot facility for balancing.

11.

Check that adapter assembly (9) and drive shaft

assembly (12) have the same vibro-engraved

or stenciled serial number. If stenciled serial

number is not readable, check that the

vibro-engraved serial number in the adapter

assembly and drive shaft assembly match with

serial number recorded in DA FORM 2410 or

2408-16.

12.

Apply a light coat of grease (E190) to splines of

adapter assembly (9) and drive shaft assembly

(12). Wipe off excess grease with cloth (E120).

Wear gloves (E184.1).

13.

Align leg (19) marked as number 1 on adapter

assembly (9) with leg marked as number 2 on

the drive shaft (12) adapter flange (14). Install

adapter assembly (9) on the splines of drive shaft

assembly (12).

NOTE

If new retainer assembly is not

available, a used retainer assembly

may be used, provided the two nylon

inserts are present.

14.

Check retainer assembly (8) for presence of

two nylon self-locking inserts. Coat threads

of retainer assembly threads with antiseize

compound (E75). Wear gloves (E184.1). Install

retainer assembly in drive shaft assembly

(12). Check for a run on torque of at least 60

inch-pounds for a used retainer assembly or

180 inch-pounds for a new retainer assembly.

15.

Torque retainer assembly (8) to 1500

inch-pounds. Continue to tighten retainer

assembly until slot in retainer aligns with holes in

the adapter assembly (9). Install cotter pin (7),

with head on the inside of the retainer assembly

(8).

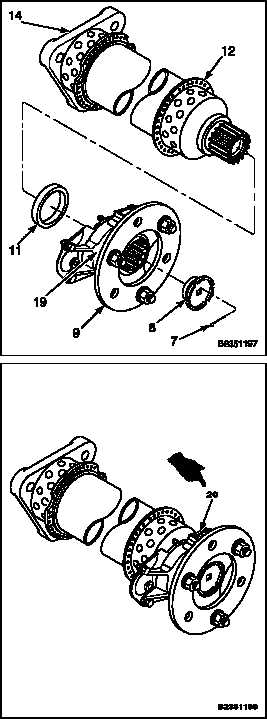

16.

Add grease (E190) at fitting (20).

INSPECT

FOLLOW-ON MAINTENANCE:

None

END OF TASK

6-50

Change 1