TM 55-1520-240-23-5

6-10.1

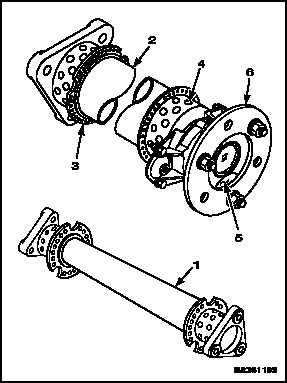

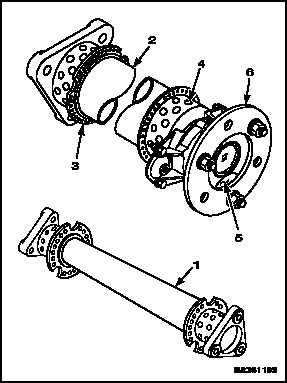

CLEAN AND INSPECT DRIVE SHAFTING OFF AIRCRAFT (Continued)

6-10.1

NOTE

Inspect all drive shafts in the same

way. Typical shaft shown.

Rotate shaft as needed to complete

check.

Tube and adapter are balanced

together. If one is damaged, both

must be replaced.

1.

Inspect shaft (1) for damage listed below. There

shall be no such damage.

a.

Cracks in tube (2).

b.

Dents in tube (2) more than 1 inch diameter

or 0.040 inch deep.

c.

Distance between any two dents less than

4.5 inches.

d.

More than one dent around tube (2) at any

one point.

e.

Distance between end flange (3) and any

dent less than 1.25 inches.

f.

Loose or cracked rivets (4) at ends of tube.

NOTE

Adapters have a shotpeened surface.

Damage cannot be repaired.

g.

Cracks, nicks, scratches, or gouges in

adapter (5). Use a 5X magnifying glass to

check.

h.

Cracks in plates (6). Use 5X magnifying

glass to check.

i.

Nicks on inside edge of plates (6). Use a

pointed scribe to check.

j.

Cracks, nicks, scratches or gouges in dents

in tube (2). Use Fluorescent Inspection to

check (TM 1-1500-335-23).

k.

Inspect for corrosion. If no corrosion is found,

perform only steps 2 and 3.

NOTE

Vibro-engraved factory markings on

tube are allowed.

2.

Inspect for nicks, scratches, or gouges in tube (2)

or plates (6). Repair damage (Task 6-11).

3.

Visually inspect tubes (2) for circumferential

scoring. Observe following limits:

a.

Depth after blending: 0.010 inch maximum.

b.

Length after blending: 2.0 inches maximum.

c.

Width after blending: 0.40 inch maximum.

d.

Minimum distance from adapter rivets is: 7

inches, each end.

e.

Minimum axial distance between

circumferential scoring repairs is 4.5 inches.

f.

Maximum of one circumferential scoring

repair around tube outer diameter (OD) at

any one point.

Change 1

6-35