TM 55-1520-240-23-5

6-7

INSPECT FORWARD DRIVE SHAFT ADAPTER ASSEMBLY

(Continued)

6-7

NOTE

Inspect all adapter assemblies in

same way. Typical assembly shown.

Use magnifying glass to inspect.

Rotate adapter assembly as needed

for complete check.

If more than one bolt is loosened

or removed from adapter assembly,

the adapter assembly must be

rebalanced.

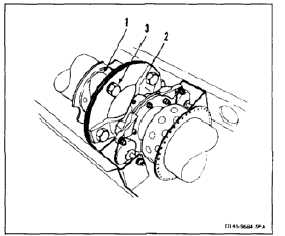

1.

Inspect adapter (1) and plates (2) for cracks. Pay

special attention to areas around bolts (3). There

shall be no cracks. If a crack is suspected in

adapter or plate, refer to TM 1-1520-253-23.

2.

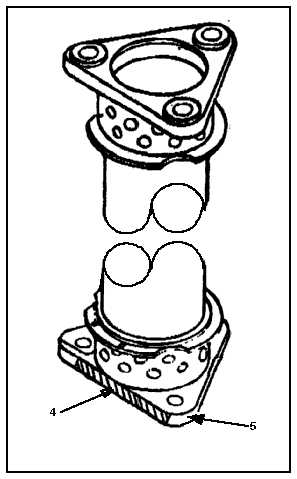

Inspect adapter (1) as follows:

a.

Nicks, gouges, score marks and scratches

that do not exceed 0.010 inch in depth on

adapter surfaces between lugs (4), including

balancing flanges can be blended per Task

6-11.

b.

Nicks, gouges, score marks and scratches

that do not exceed 0.020 inch in depth on

adapter, adjacent to the bolt hole outer lug

surfaces (5) can be blended per Task 6-11.

c.

Light damage such as nicks, score marks,

and scratches on the adapter external

surfaces that do not exceed 0.005 inch in

depth (except for the bolt holes) can be

blended per Task 6-11.

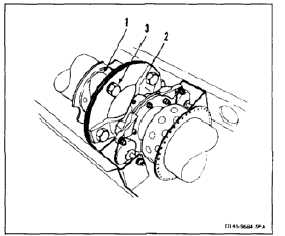

3.

Inspect plates (2). There shall be no sharp dents

or distorting. There shall be no nicks on inside

edge. Feel for nicks with pointed scriber.

4.

Inspect outside edge of plates (2) for light

scratches, fretting corrosion or nicks. Repair

damage (Task 6-11). Use abrasive paper (E15).

FOLLOW-ON MAINTENANCE:

Close aft pylon lower fairing (Task 2-2).

Close aft pylon doors (Task 2-2).

Close forward transmission fairing work platforms

(Task 2-2).

Close forward drive shaft tunnel access covers (Task

2-2).

END OF TASK

6-24