TM 55-1520-240-23-5

6-35

REPAIR TRANSMISSION SUMP (AVIM)

(Continued)

6-35

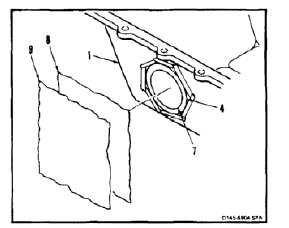

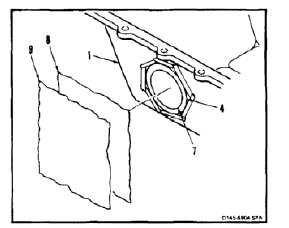

14.

Check that repair is slightly higher than surface

of sump (1). Add more pieces of fabric under

top patch (7), if needed.

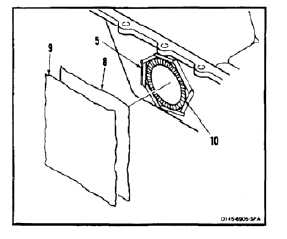

15.

Cover repair and cleaned area (4) with

peel ply (E270) (8). Cover peel ply with

Teflon-impregnated fabric (E170) (9).

16.

Place weight on repair area to provide 2 to 3 psi

pressure. Use shot bags or equivalent.

If temperature exceeds 180ºF (80ºC),

sump can be damaged.

17.

Cure resin at 140º to 160ºF (60º to 70ºC) for

2 hours. Use infrared lamp and temperature

indicating strips (E413).

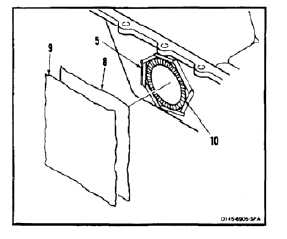

18.

Remove weight, Teflon-impregnated fabric (9)

and peel ply (8). Remove Teflon tape (5).

19.

Sand squeezeout (10) until repair area is smooth.

Use abrasive paper (E7).

Protective gloves (E184.1) shall be

worn during the remainder of this

task; otherwise, personal injury could

result.

20.

Clean the repair area with acetone (E20) and

clean cloths (E120). Wear gloves (E184.1).

21.

Sand the repair area with abrasive paper (E10).

Clean the area with acetone (E20) and clean

cloths (E120).

22.

Apply one coat of epoxy primer (E292 or E293).

Allow the primer to dry.

23.

If the sump is from a forward or aft transmission,

apply two coats of epoxy coating (E166). Allow

the coating to dry.

24.

If the sump is from a combining transmission,

finish the repair area with two coats of black

lacquer (E462) or polyurethane (E285.1), as

determined by the following:

a.

Apply methyl-ethyl-ketone (MEK) (E244) to a

small area of the topcoat near the area to be

refinished. Use brush (E86).

b.

Wipe the area. If the topcoat wipes away, use

lacquer (E462). If the topcoat is unaffected,

use polyurethane (E285.1).

INSPECT

FOLLOW-ON MAINTENANCE:

None

END OF TASK

6-115