TM 55-1520-240-23-4

5-126.2

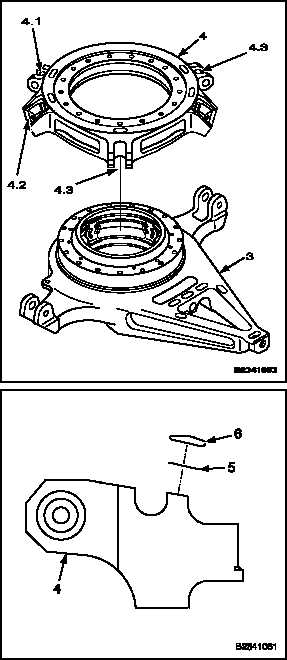

INSTALL SWASHPLATE ROTATING RING INTERRUPTER BRACKETS

(AVIM) (Continued)

5-126.2

1.

Carefully lift rotating ring assembly (4) from

stationary ring (3). Use a mallet to separate the

rings, if needed.

2.

Mark bracket locations on the bottom of rotating

ring (4).

NOTE

Three brackets are installed on

forward swashplate only. One bracket

has two interrupters. The dual

interrupter is installed at the first pitch

change link mount (4.1) (clockwise)

from the forward drive arm mounting

lug (4.2). The single interrupters

are installed at the remaining pitch

change link mounting locations (4.3).

3.

Sand rotating ring surface lightly to remove

adhesive. Use abrasive paper (E7).

4.

Sand bracket surface lightly to remove adhesive.

Use abrasive paper (E6).

5.

Wipe sanded area with cloth (E120) damp with

acetone (E20). Wipe dry with a clean cloth

before acetone evaporates. Wear gloves (E186).

6.

Cut scrim cloth (E326) to size of brackets.

7.

Mix a small amount of adhesive (E43) as follows:

WARNING

Adhesive (E43) is toxic. It can

irritate skin and cause burns. Avoid

inhaling. Use only with adequate

ventilation. Avoid contact with skin,

eyes, or clothing. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

a.

If adhesive (E43) is used, mix 5 parts of

white base and 7 parts of gray hardener.

Use trip balance. Stir in polyethylene cup

(E157) with wood spatula (E424) until color is

uniform. Use gloves (E186).

NOTE

Working life of adhesive (E43) is

about 30 minutes.

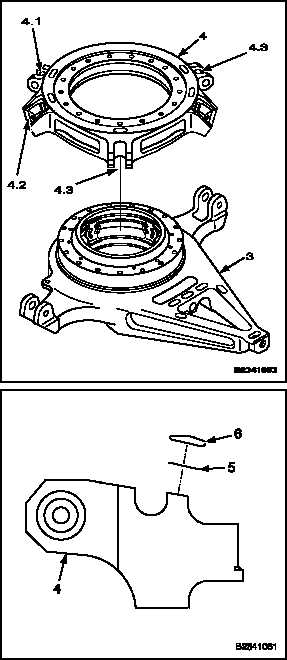

8.

Apply even coat of adhesive (E42) to mating

surfaces of brackets (6) and rotating ring (4).

Wear gloves (E186).

9.

Press scrim cloth (E326) (5) into adhesive on

rotating ring by hand.

10.

Apply even coat of adhesive over scrim cloth

(E326) (5). Do not allow bubbles or lumps to

form. Wear gloves (E186).

5-708

Change 2