TM 55-1520-240-23-4

5-126.2

INSTALL SWASHPLATE ROTATING RING INTERRUPTER BRACKETS

(AVIM) (Continued)

5-126.2

11.

Install brackets (6) on rotating ring (4) by hand.

12.

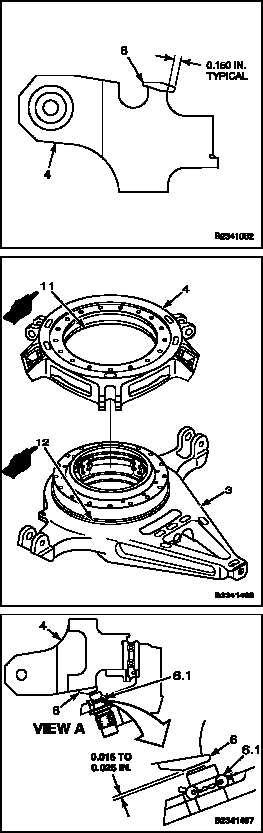

Check that clearance between end of brackets

(6) and rotating ring (4) is 0.150 inch.

13.

Apply pressure to seat each bracket and squeeze

out excess adhesive. Make sure brackets do

not move.

14.

Wipe excess adhesive from brackets. Use cloth

(E120) damp with methyl-ethyl-ketone (E244).

Wear gloves (E186).

15.

Cure adhesive at 150 to 160 F (66 to 71 C) for

2 hours. Use heat lamp. Monitor temperature.

Use temperature indicating strips (E413).

CAUTION

Curing time increases rapidly as

temperature decreases. Adhesive

(E43 or E47.1) will not cure below

60 F (15 C). Do not count as cure

time any period when temperature is

below 70 F (21 C).

NOTE

If heat lamp is not available, a

serviceable cure can be achieved

at 70 to 80 F (21 to 27 C) in 24

hours.

16.

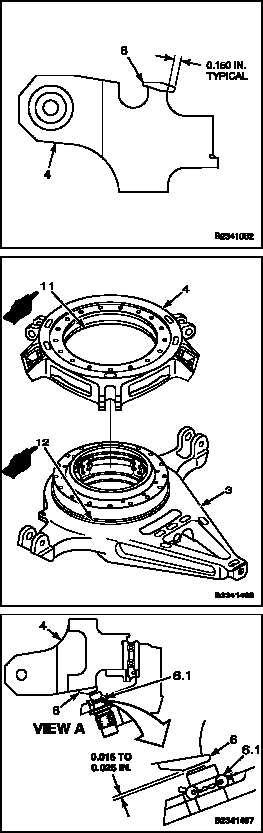

Coat lip of seal (11) and running surface (12) on

stationary ring (3) with grease (E190).

17.

Install rotating ring assembly (4) on stationary

ring (3). Use a mallet, if needed.

17.1. Position bracket (6) over phase detector (6.1)

by turning rotating ring (4) by hand. Check

clearance between each of the three interrupter

brackets (6) and phase detector (Magnetic

Pickup (6.1)). Clearance should be 0.015 to

0.025 inch.

INSPECT

FOLLOW-ON MAINTENANCE:

None

END OF TASK

Change 2

5-709