TM 55-1520-240-23-4

5-98

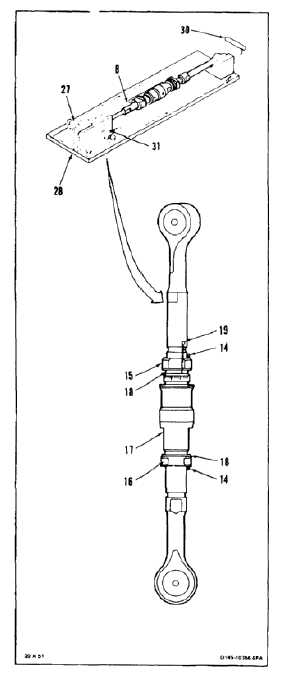

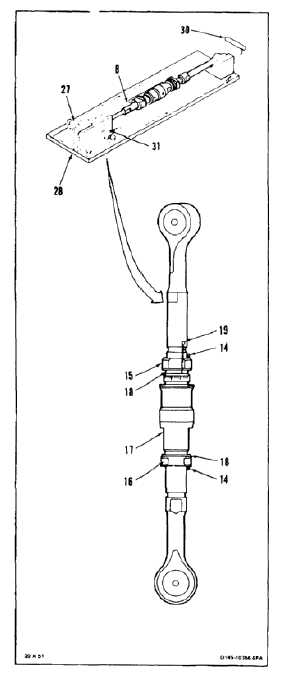

REPAIR PITCH LINK

(Continued)

5-98

Do not hold rod-end at opposite end of

pitch link when checknut is tightened.

Do not turn upper checknut clockwise

or lower checknut counterclockwise

to tighten. Damage to pitch link can

occur.

11.

Torque upper and lower checknuts (15 and 16)

to 1050 to 1300 inch-pounds.

12.

Install cotter pins (14). Keep split ends within

outside of indicator sleeves (18) to avoid boot

damage.

13.

Lockwire turnbuckle (17) to hole in pin (19). Use

lockwire (E231).

14.

Remove pitch link (8) from assembly fixture (T78)

(25) as follows:

a.

Remove pins (30 and 31).

b.

Loosen handknob (27). Move sliding angle

(28) clear.

c.

Remove pitch link (8).

INSPECT

FOLLOW-ON MAINTENANCE:

None

END OF TASK

5-599