TM 55-1520-240-23-4

5-99.1

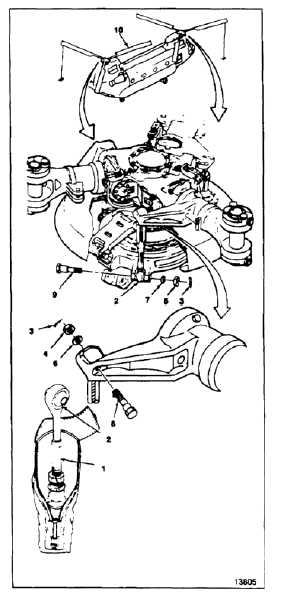

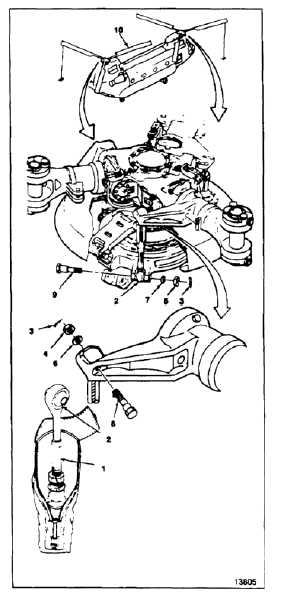

PITCH LINK BOLT TORQUE CHECK

(Continued)

5-99.1

NOTE

Torque on nuts at upper and lower

bolts is checked in the same way for

all pitch links.

1.

Inspect pitch link (1) for looseness or damage

caused by chafing. Inspect bearing (2) at each

end of link for liner unbonding and signs of

seizing. If a crack in the pitch link is suspected,

refer to TM 1-1520-253-23.

2.

Remove cotter pin (3) at each end of link (1).

3.

Apply 400 inch-pounds torque to nuts (4 and 5)

in the tightening direction.

NOTE

The nuts should not move.

4.

If nuts (4 and 5) did not move during torque

check, install a new cotter pin (3). Go to

Follow-On Maintenance.

5.

If nuts (4 or 5) moved during torque check,

remove nut, washer (6 or 7), and bolt (8 or 9)

(Task 5-94.1).

6.

Inspect bolt (8 or 9) for obvious wear. If bushing

has damage, it may be reworked (Task 1-14).

If shank of bolt has scratches or other damage

0.005 inch deep or more, or has a wear step of

0.005 inch or more, replace bolt (Task 5-94.1).

a.

Have helpers lift and twist blade (10) as

required to install bolt (8 or 9). Keep blade

supported.

b.

Install new bolt (8 or 9), washer (6 or 7),

and new nut (4 or 5). Check that limiter

is installed. Torque nut to 400 to 660

inch-pounds. Install cotter pin (3).

7.

Have helpers lower rotary-wing blade (10).

INSPECT

FOLLOW-ON MAINTENANCE:

None

END OF TASK

5-604