TM 55-1520-240-23-4

5-66.2

REPAIR TITANIUM NOSE CAP CRACKS (AVIM)

(Continued)

5-66.2

The preparation and bonding of the

titanium nose cap doubler is a critical

repair. It must be performed exactly

as described. If possible, surface

preparation and bonding shall be done

in a controlled environment to avoid

contamination and to obtain proper

adhesive cure. Failure to follow these

instructions can result in unbending

of the doubler and subsequent injury

to personnel.

Do not repair titanium nose cap cracks

outboard of sta. 303.

NOTE

There is no limit to the number

of repairs that can be done on a

nose cap. The minimum distance

between repairs, measured between

centerlines, shall be 12 inches. If

cracks occur closer than 12 inches,

blade is not reparable at this level.

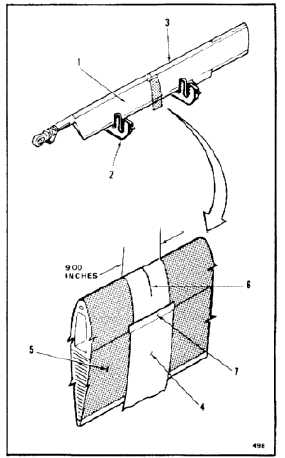

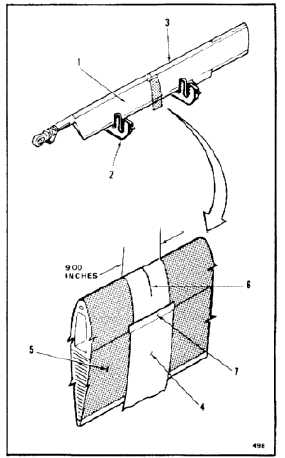

1.

Position blade (1) in adapter (T164) (2) with nose

cap (3) up.

2.

Tape polyvinyl sheets (E284) (4) over top and

bottom of blade (5) aft of crack (6). Use masking

tape (E388) (7).

Remove only black lacquer or

polyurethane paint finish. Green

primer must remain to provide

satisfactory bond. If bare titanium is

exposed, DeSoto primer (E291.1)

must be applied.

Do not use chlorinated solvents on

titanium nose cap or doubler. These

solvents cause material failure.

2.1.

Determine the finish system used on the rotor

blade (TM 55-1500-344-23).

3.

Remove black lacquer or polyurethane paint

from strip 4-1/2 inches wide on each side of

crack (6) on both sides of cap (3). Use abrasive

paper (E9). Use very light pressure. Sand only

as required to remove lacquer.

5-311