TM 55-1520-240-23-4

5-66.1

REPAIR OF NOSE CAP OR EROSION CAP UNBONDING

(Continued)

5-66.1

8.

Position blade (7) so void (1) is level.

9.

Fill void (1) with adhesive (E43). Use clean 0.005

inch shim stock to work adhesive into void. Fill

deepest part of void first to prevent trapping of air.

10.

Close void (1). Press cap (4) against blade by

hand. Remove excess adhesive. Use cloth

(E120).

11.

Remove tape (5) and aluminum foil (6).

12.

Cure repair as follows:

a.

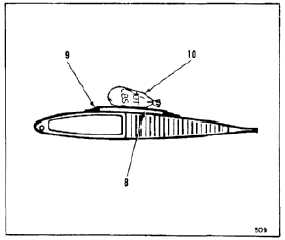

Cover the repair with peel ply (E270) (8).

b.

Cut piece of 1/4 inch thick rubber sheet

(E321) to cover repair. Position rubber sheet

(9) over peel ply (8).

c.

Apply pressure of 2 to 3 pounds for each

square-inch of repair; Apply pressure evenly

over repair. Use shot bags (10).

Blade temperature must not exceed

160ºF (71ºC). Overheating will

damage fiberglass.

d.

Cure repair at 140º to 160ºF (60º to 71ºC)

for 2 hours. Use heat lamps. Monitor blade

temperature. Use temperature indicating

strips (E413).

NOTE

If heat lamps are not available, cure at

70ºF (21ºC) for 24 hours. Shot bags

can be removed after 12 hours.

13.

Remove shot bags (10), rubber sheet (9), and

peel ply (8).

5-308