TM 55-1520-240-23-3

4-122

INSTALL AND RIG ENGINE DROOP ELIMINATOR VARIABLE RESISTORS

(Continued)

4-122

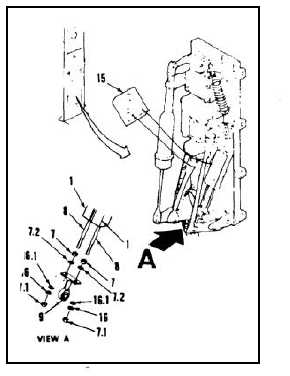

6.

Remove two nuts (7.1) and two washers (16).

7.

Adjust shaft (8) until multimeter (15) reads 30

to 35 ohms.

8.

Install two washers (16), two lockwashers

(16.1) and two nuts (7.1). Torque nuts to 25

inch-pounds. Check nuts for thread protrusion.

If all threads on nut are not engaged, replace

engine droop eliminator variable resistors (1)

(Tasks 4-119 and 4-122).

9.

Tighten two nuts (7) against link (9). Torque nuts

to 25 inch-pounds. Make sure link (9) is parallel

to resistor shafts (8).

NOTE

Use the following hardware to

connect wiring to resistors: screws

MS35275-202, washers AN960C3L,

and lockwashers MS35340-39 or

equivalent.

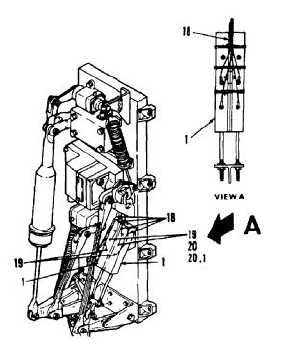

10.

Remove tape from ends of eight wires (18).

Connect eight wires to resistors (1) by installing

eight screws (19), eight lock washers (20), and

eight washers (20.1). Remove tags from wires.

11.

Secure wires (18) to resistors (1). Use twine

(E433).

FOLLOW-ON MAINTENANCE:

Adjust engine droop eliminator variable resistors

(Task 4-118).

Install controls closet panel (Task 2-2).

Install controls closet acoustic blanket (Task 2-108).

END OF TASK

4-426