TM 55-1520-240-23-3

4-41

INSPECT CONNECTING LINK (DRAG STRUT) AND ENGINE MOUNT

FITTINGS

(Continued)

4-41

NOTE

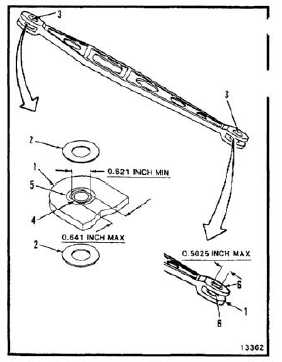

Procedure can be used for No. 1 or

No. 2 engine connecting link and

fittings. Link and fittings for No. 1

engine are shown.

1.

Clean link (1) and two washers (2). Use solvent

(E162) and cloth (E135). Wear gloves (E186).

2.

Check surface of link (1) for nicks, scratches, and

gouges. Damage in areas other than bores (3)

is acceptable if it does not exceed 0.040 inch

or 10 percent of material thickness, whichever

is less. If a crack is suspected in the connecting

link, refer to TM 1-1520-253-23.

3.

Inspect bushing (4) for wear. Outside diameter

shall not be less than 0.621 inch.

4.

Measure inside diameter of insert (5) across flats.

Inside diameter shall not exceed 0.641 inch.

5.

Measure two washers (2). Washers shall be

0.015 inch to 0.035 inch thick. Maximum

allowable reduction of thickness at wear spots

is 0.002 inch.

6.

Inspect bushings (6) on lower end of link (1).

Inside diameter shall not exceed 0.5025 inch.

7.

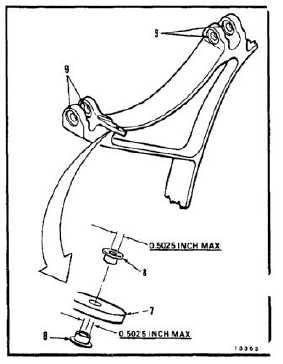

Clean fitting (7) and two bushings (8). Use

solvent (E162) and cloth (E135). Wear gloves

(E186).

8.

Check surface of fitting (7) for nicks, scratches,

and gouges. Damage in areas other than bores

(9) is acceptable if it does not exceed 0.040 inch

or 10 percent of material thickness, whichever

is less.

9.

Inspect two bushings (8) in fitting (7). Inside

diameter shall not exceed 0.5025 inch.

4-215