TM 55-1520-240-23-3

4-37

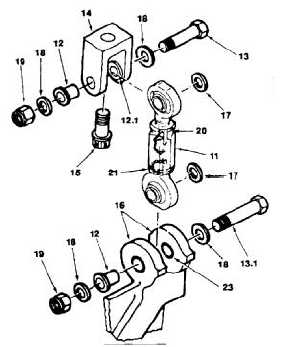

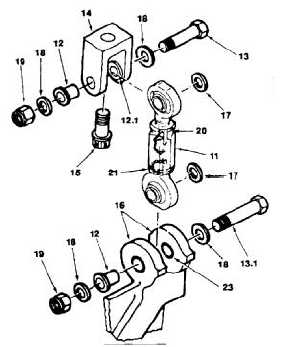

INSPECT AFT ENGINE MOUNT LINK AND ADAPTER PARTS

(Continued)

4-37

INSPECT AFT ENGINE MOUNT LINK AND ADAPTER

WITH 57

11.

Clean link (11), four bushings (12, 12.1, and 23),

two bolts (13 and 13.1), adapter (14), adapter

bolt (15), and aft engine mount lugs (16) on

structure. Use solvent (E162) and cloth (E135).

Wear gloves (E186.1).

12.

Inspect link (11), four bushings (12, 12.1, and

23), two bolts (13 and 13.1), bolt (15), and

adapter (14). There shall be no cracks, gouges,

scratches, or dents, which exceed 10 percent

of material thickness or 0.040 inch. Whichever

is less. If a crack is suspected in the aft engine

mount link or the aft engine mount, refer to TM

1-1520-253-23.

13.

Inspect lockwire on engine mount link for breaks.

14.

Inspect torque stripe of link body and jam-nuts

(21) for breaks.

NOTE

During the inspection of the aft

engine mount lugs, inspect for cracks

originating from the inboard lug recess

at the bolt hole.

15.

Inspect lugs (16) on structure. There shall be

no cracks, gouges, scratches, or dents deeper

than 0.040 inch.

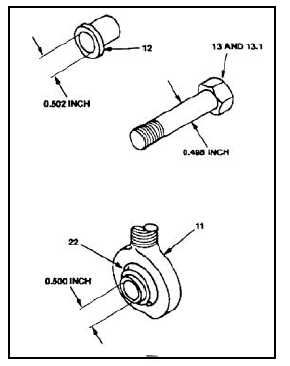

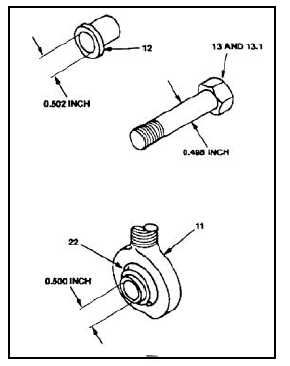

16.

Measure inside diameter of four bushings (12).

Diameter shall not be more than 0.502 inch.

17.

Measure inside diameter of two bearings (22).

Bearing diameter shall not be more than 0.500

inch.

18.

Measure shank diameter of two bolts (13 and

13.1). Diameter shall not be less than 0.495

inch.

19.

Use a dial indicating scale to apply a 25 to 50

pound load to bearing (22) in axial direction.

Apply a 25 to 50 pound load to bearing (22) in

opposite direction. Measure axial play. Play shall

not be more than 0.006 inch.

20.

Apply a 25 to 50 pound load to bearing (22) in

radial direction. Apply a 25 to 50 pound load to

bearing (22) in opposite direction. Measure radial

play. Play shall not be more than 0.006 inch.

21.

Repeat steps 19 and 20 four times for each

bearing (22). Rotate bearing 90º each time.

FOLLOW-ON MAINTENANCE:

None

END OF TASK

4-199