TM 55-1520-240-23-3

4-12

ASSEMBLE POWERPLANT

(Continued)

4-12

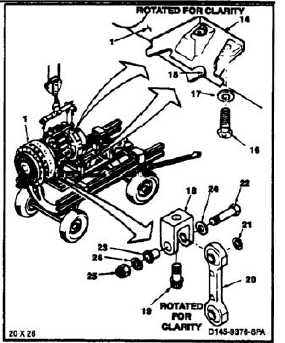

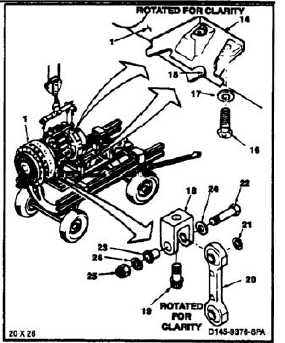

5.

Position two adapters (14) so holes in adapters

align with holes in powerplant (1). Make sure

curved surfaces (15) of adapters are down.

Shipping and mounting hardware are

similar. Ensure correct hardware is

used during powerplant assembly.

Otherwise, damage to powerplant and

aircraft as wail as injury to personnel

may occur.

6.

Install eight bolts (16) and washers (17). Torque

bolts to 300 to 450 inch-pounds. Lockwire

bolts. Use lockwire (E231).

7.

Position adapter (18) on powerplant (1) and

install bolt (19). Torque bolt to 400 inch-pounds.

Lockwire bolt. Use lockwire (E231).

8.

Align hole in link (20) and spacer (21) with holes

in adaptor (18). Install bolt (22), bushing (23),

two washers (24), and nut (25). Torque nut (25)

to 375 inch-pounds to seat bushing. Loosen nut

and retorque to 20 inch-pounds above run on

torque. Not to be less than 70 inch-pounds.

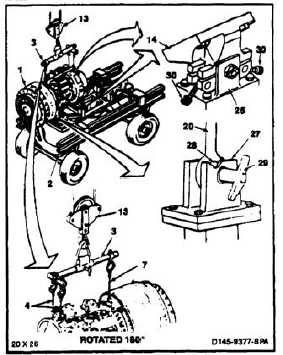

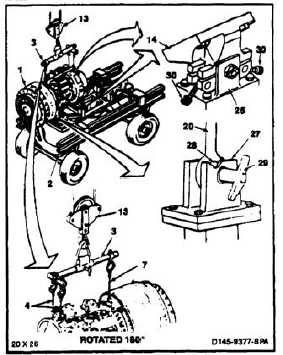

9.

Position powerplant (1) over powerplant adapter

(T16). Make sure forward engine mount adapters

(14) and aft link (20) align with adapter fittings

(26 and 27).

During lowering of powerplant to

adapter, make sure bearing in aft

engine mount link does not tilt in clevis

of adapter fitting. If bearing tilts, it will

wedge in clevis, causing damage to

bearing and clevis.

10.

Lower hoist (13) slowly until powerplant (1)

weight is on adapter (2). Make sure bearing (28)

in aft mount link (20) does not tilt or wedge in

clevis of adapter fitting (27).

11.

Install pin (29) through link (20) and adapter

fitting (27).

12.

Raise four bolts (30) over engine mount adapters.

Tighten bolts.

13.

Disconnect hoist (13) from sling (3).

14.

Disconnect three cables (4 and 7) and remove

sling (3).

4-95