TM 55-1520-240-23-10

16-1

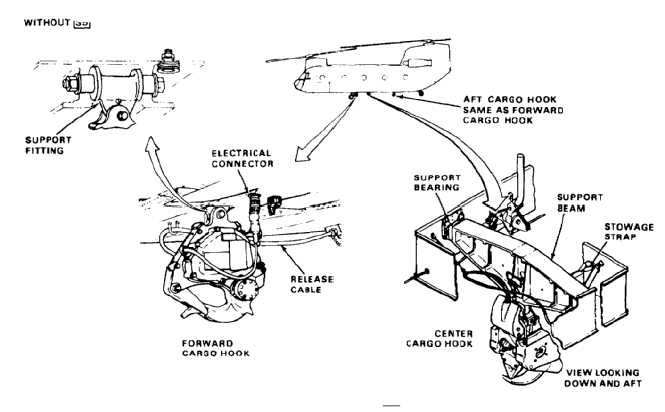

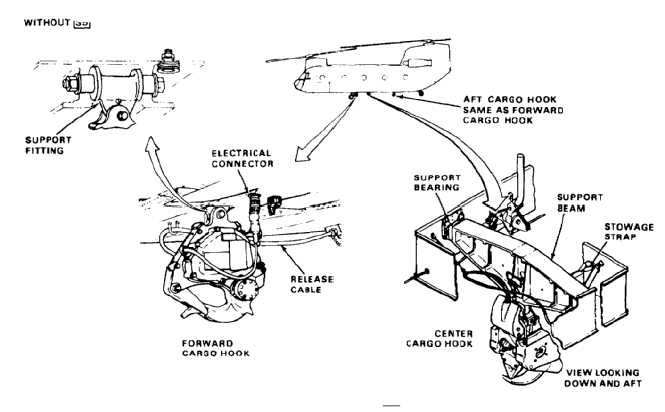

EXTERNAL CARGO HOOK SYSTEM

16-1

DESCRIPTION

The external cargo hook system consists of three

separate cargo hooks mounted on the underside of the

helicopter. The system allows a single load to be carried

suspended at up to three points or three separate loads

to be carried at the same time.

NO BREAK - WORK HARDER

The center cargo hook is suspended from a beam under

the cabin floor at sta. 331. The hook is attached to the

beam with a bolt that lets the hook swing to each side.

The beam is carried in bearings attached to structure at

the sides of the rescue hatch in the floor. It can pivot

forward and aft from the attaching points.

NO BREAK - WORK HARDER

When not in use, the hook is stowed between cabin floor

and rescue hatch door. In use, the hatch door is opened

and the hook is unstrapped to hang down through the

open hatch. The hook lifting capacity is 26,000 pounds.

NO BREAK - WORK HARDER

The forward and aft hooks hang from fittings attached

to the floor beams at sta. 249 and 409. Each fitting is

a universal type that allows the hook to swing forward

and aft and from side to side. Normally the hook is

electrically actuated through a connector on the fuselage

skin. It can also be released manually through a cable

that connects to a release mechanism. The lifting

capacity of each hook is 17,000 pounds. When used

together, the two hooks can lift a load of 25,000 pounds.

NO BREAK - WORK HARDER

All three hooks can be released in any one of three

modes: normal, emergency, or manual. See Task 16-2

for a description of hook operation in each of these

modes.

NO BREAK - WORK HARDER

Power to operate the cargo hook system in normal

operation comes from the No. 2 28 vdc bus. Two circuits

are provided, each controlled by a separate circuit

breaker. One circuit provides power to the system. The

other contains the control switches and relays. Two

separate power and control circuits are provided for

emergency release of the hooks. Again, each has its

own circuit breaker.

16-2