TM 55-1520-240-23-9

11-237

INSTALL TUNNEL CONNECTING LINKS

(Continued)

11-237

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured.

Ensure that both rod end jam nuts are

installed and torqued.

Ensure that the rivet through the fixed

rod end insert and rod end is secure.

Ensure rivet, roll pin, and associated

hardware through rod end insert at

adjustable end of link assy is secure.

Ensure proper application of ALBI fire

retardant coatings to the link assy.

Ensure the bushing is installed on the

bolt head side of the clevis on the

forward end of this link. Omission of

this bushing will result in improper

joint stack-up.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

Do not install connecting link unless it

is same length as link being replaced.

If length is not same, connecting

link can cause flight controls to be

out-of-rig.

NOTE

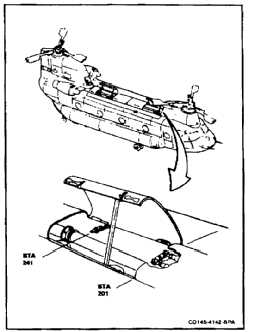

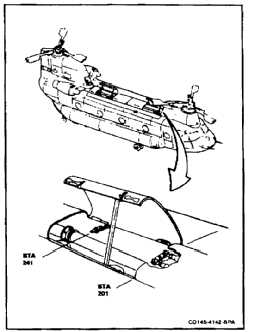

Procedure is same for all tunnel

connecting links. Links are connected

at sta. 201, 241, 281, 321, 361, and

401. Connecting links at sta. 241 are

shown here.

All bolts installed in flight control

system are self-retaining impedance

type bolts. During installation of flight

controls make sure all bolts used are

self-retaining bolts (Task 1-13).

11-923