TM 55-1520-240-23-9

11-96

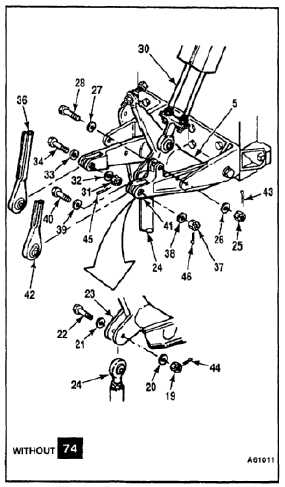

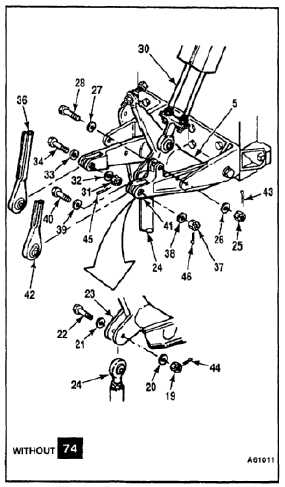

INSTALL PALLET THRUST IDLER BELLCRANK

(Continued)

11-96

l.

Remove nut (19), two washers (20 and 21),

and bolt (22) from lugs (23) of bellcrank (5).

m.

Position input connecting link (24) between

lugs (23) of bellcrank (5). Install bolt (22), two

washers (21 and 20), and nut (19). Do not

torque nut at this time. Remove tag from link.

n.

Remove nut (25), two washers (26 and 27),

and bolt (28) from lugs (29) of bellcrank (5).

o.

Position droop eliminator potentiometer (30)

between lugs (29) of bellcrank (5). Install bolt

(28), two washers (27 and 26), and nut (25).

Do not torque nut at this time. Remove tag

from potentiometer.

p.

Remove nut (31), two washers (32 and 33),

and bolt (34) from lugs (35) of bellcrank (5).

q.

Position damper connecting link (36) between

lugs (35) of bellcrank (5). Install bolt (34), two

washers (33 and 32), and nut (31). Do not

torque nut at this time. Remove tag from link.

r.

Remove nut (37), two washers (38 and 39)

and bolt (40) from lugs (41) of bellcrank (5).

s.

Position CCDA connecting link (42) between

lugs (41) of bellcrank (5). Install bolt (40), two

washers (39 and 38), and nut (37). Do not

torque nut at this time. Remove tag from link.

t.

Torque nut (25) to 15 to 20 inch-pounds.

Install cotter pin (43).

u.

Torque three nuts (19, 31, and 37) to 30 to

45 inch-pounds. Install three cotter pins (44,

45, and 46).

v.

Check four bolts (22, 28, 34, and 40). Bolts

shall not rotate with torque less than 10

inch-pounds. There shall be no axial

looseness. If bolt rotates or is loose, add

washer under nut, and repeat step t or u.

INSPECT

11-506