TM 55-1520-240-23-9

11-78

ASSEMBLE COPILOT’S COCKPIT CONTROL ASSEMBLY

(Continued)

11-78

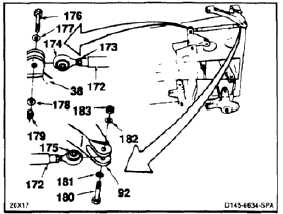

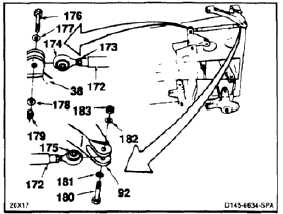

90.

If thrust connecting link (172) is a replacement,

loosen nut (173) of adjustable end. Turn bearing

(174) 90º to bearing (175). Torque nut to 100

inch-pounds.

91.

Position link (172) in bellcrank (38) upper arm,

fixed end toward bellcrank. Install bolt (176), two

washers (177 and 178), and nut (179). Do not

tighten nut at this time.

92.

Position link (172) in short arm of bellcrank (92).

Install bolt (180), two washers (181 and 182),

and nut (183). Do not tighten nut at this time.

Remove tag from link.

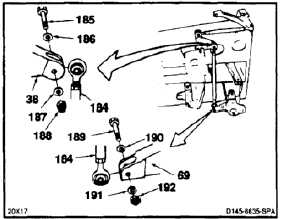

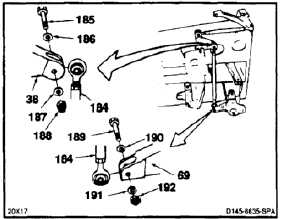

93.

Position thrust connecting link (184) in bellcrank

(38), fixed end toward bellcrank. Install bolt

(185), two washers (186 and 187), and nut (188).

Do not tighten nut at this time.

94.

Position link (184) in long arm of bellcrank (69).

Install bolt (189), two washers (190 and 191),

and nut (192). Do not tighten nut at this time.

Remove tag from link.

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured.

Ensure that both machined rod ends

attached to the link are secure.

Ensure that both rod end jam nuts are

installed and torqued.

Ensure that the rivet through the fixed

rod end bearing is secure.

Ensure painted band on control rod

faces towards pilot. (AFT)

Ensure rod end bearing faces aft

attaching to socket assembly.

At installation of this component,

ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

11-396