TM 55-1520-240-23-9

11-58

RIG AFT ROTARY WING BLADES

(Continued)

11-58

NOTE

Rigging tool (T129) or protractor can

be used to measure rotary wing blade

angles. Using tool (T129), perform

steps 4 thru 18. Using protractor,

perform steps 19 thru 26.

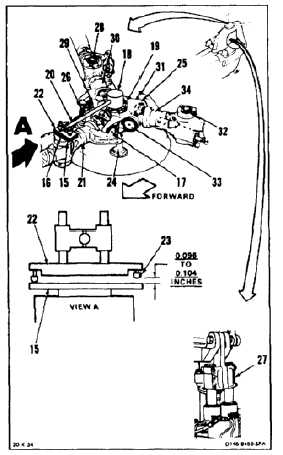

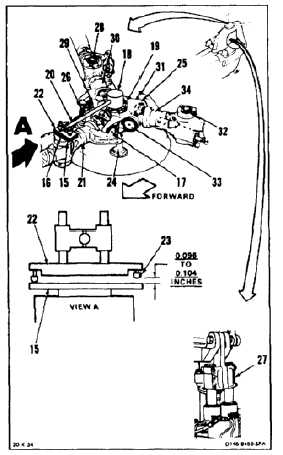

4.

Working from aft left work platform install plate

(15) in vertical pin (16) parallel to horizontal pin

(17).

5.

Install tool (T129) (18) in rotor shaft (19). Position

arm (20), parallel to pitch housing (21) with plate

(22) parallel and on plate (15).

6.

Measure gap between ball (23) and plate (15).

Gap must be 0.096 to 0.104 inches. If not, adjust

pitch link (24) (Task 5-94), then repeat step 6.

7.

Position tool (18) away from plate (15). Remove

plate from pin (16).

8.

Turn rotor hub (25) and position pitch link (26)

above aft left servocylinder (27).

9.

Install plate (15) in pin (28) parallel to horizontal

pin (29).

10.

Position arm (20) parallel to housing (30) with

plate (22) parallel and on plate (15).

11.

Repeat step 6 for pin (28) and link (26).

12.

Position tool (18) away from plate (15). Remove

plate from pin (28).

13.

Turn rotor hub (25) and position pitch link (31)

above aft left servocylinder (27).

14.

Install plate (15) in pin (32) parallel to pin (33).

15.

Position arm (20) parallel to housing (34) with

plate (22) parallel and on plate (15).

16.

Repeat step 6 for pin (32) and link (31).

17.

Remove tool (18) from shaft (19).

18.

Remove plate (15) from pin (32), then go to step

26.

11-271