TM 55-1520-240-23-9

11-54

RIG FORWARD OR AFT SWASHPLATE AND SERVOCYLINDERS

(Continued)

11-54

NOTE

Do not allow bearing to turn when

tightening nut.

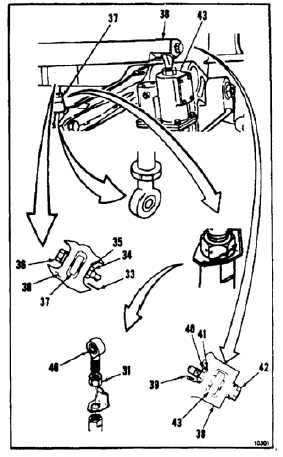

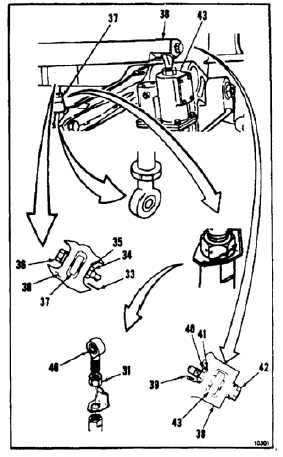

22.

Hold bearing (46) and tighten nut (31). Torque

nut to 450 inch-pounds. Lockwire nut to clip.

23.

Have helper hold link (37) and actuator (43).

Position link and actuator in swashplate.

Bushing must be in swashplate before

installing bolts; otherwise, damage to

components will result.

NOTE

Positive retention bolts are installed

in flight control connections. These

bolts are self-retaining and require a

special nut and torque (Task 1-13).

24.

Install bolt (42), head aft, washer (41), and nut

(40) in swashplate (38) and actuator (43). Torque

nut to 660 inch-pounds. Continue tightening

only as needed to align cotter pin holes. Do not

exceed 1400 inch-pounds. Install cotter pin

(39).

25.

Install bolt (36), head forward, washer (35), and

nut (34) in swashplate (38) and link (37). Torque

nut to 600 inch-pounds. Continue tightening

only as needed to align cotter pin holes. Do not

exceed 1400 inch-pounds. Install cotter pin

(33).

26.

If aft swashplate and servocylinders are not to be

rigged, go to step 34.

11-246