TM 55-1520-240-23-9

11-265

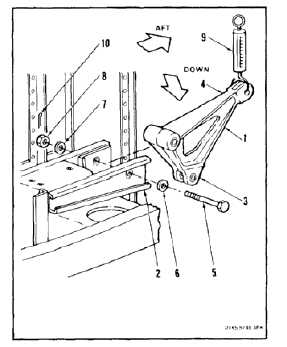

INSTALL PYLON LEFT UPPER BELLCRANK

(Continued)

11-265

c.

Check that torque on nut (8) is more than 155

inch-pounds with cotter pin hole aligned.

d.

Repeat step a.

4.

Install cotter pin (10).

NOTE

The adjustable rod ends should be

aft or up.

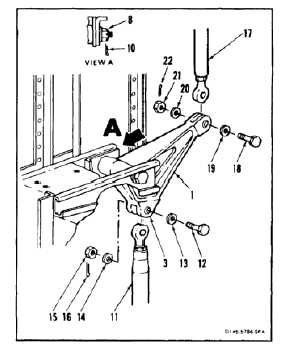

INSPECT

5.

Untie connecting link (11). Position link in short

arm (3) of bellcrank (1). Install bolt (12), two

washers (13 and 14), and nut (15).

6.

Torque nut (15) to 60 to 90 inch-pounds. Install

cotter pin (16).

7.

Position connecting link (17) in bellcrank (1).

Install bolt (18), two washers (19 and 20) and

nut (21). Remove tag.

8.

Torque nut (21) to 30 to 45 inch-pounds. Install

cotter pin (22).

9.

Check two bolts (12 and 18). Bolts shall not

rotate with torque less than 10 inch-pounds.

There shall be no axial looseness. If bolt rotates

or is loose, add washer under nut and repeat

step 6 or 8.

NOTE

If the connecting links are changed

in length, perform neutral rig check

(Task 11-33).

INSPECT

NOTE

Inspect bellcrank and connecting link

bearings (Task 11-9).

FOLLOW-ON MAINTENANCE:

Connect servocylinder connecting links (Task

11-193).

Remove safety blocks (Task 11-29).

Close pylon left work platform (Task 2-2).

Close cargo ramp (Task 2-2).

END OF TASK

11-1006