TM 55-1520-240-23-9

11-265

INSTALL PYLON LEFT UPPER BELLCRANK

(Continued)

11-265

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured at

each joint connection and mounting to

the airframe.

Ensure that all bushings are properly

installed (including orientation) in

each input and output clevis of the

bellcrank.

Ensure bellcrank hub bearings are

serviceable and properly installed.

Ensure proper orientation of bellcrank

at installation.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

NOTE

All bolts installed in flight control

system are self-retaining (impedance)

bolts. During installation of flight

controls, make sure all bolts used are

self-retaining bolts.

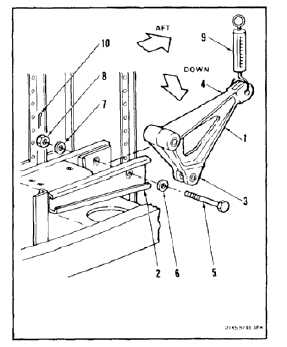

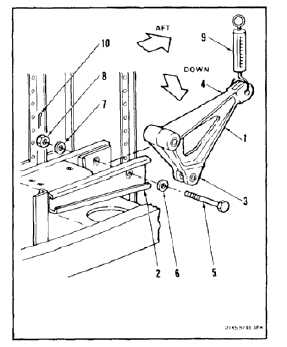

1.

Position bellcrank (1) in support (2), short arm

(3) down, long arm (4) aft. Install bolt (5), two

washers (6 and 7) and nut (8). Remove tag.

2.

Torque nut (8) to 155 to 220 inch-pounds. Align

cotter pin hole.

3.

Check bellcrank (1) as follows:

a.

Apply force to end of arm (4). Use dial

indicating scale (9). Bellcrank must rotate

with force less than 3 pounds and bolt (5)

must not turn. If bolt turns, go to step b. If

bolt does not turn go to step 4.

b.

Back off nut (8) until bolt does not turn when

bellcrank is rotated. Check cotter pin hole

is aligned.

11-1005