TM 55-1520-240-23-8

10-15

REPAIR FUEL CELL INNER LINER

(Continued)

10-15

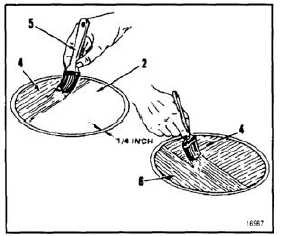

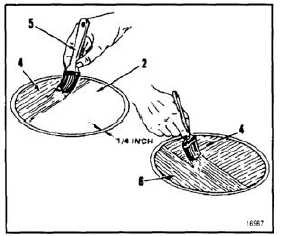

g.

Apply a uniform coat of barrier cement

(E63.3) (4) over previous coat of repair

cement (2) to within no more than 1/4 inch of

repair area of O.D. Use a brush (5). Remove

any excess cement from unbuffed area. Use

clean cloth (E120) dampened with MEK

(E244). Wear gloves (E184.1). Allow barrier

to dry to touch.

h.

Apply a second coat of barrier cement

(E63.3) (6) over first barrier coat (4) at 90º

to the application of first coat. Use a brush.

Allow second coat to air dry for approximately

30 minutes.

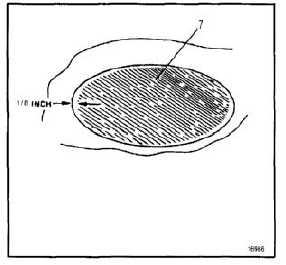

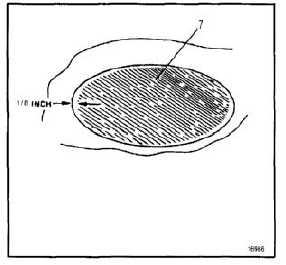

i.

Prepare repair cement (E63.2) as in steps

d and e.

j.

Carefully apply a thin uniform coat of cement

mixture (7) over previous coats of barrier

cement to within no more than 1/8 inch

of O.D. of buffed edge area. Use a brush.

Smooth surface with MEK (E244) and

remove any excess cement from unbuffed

area. Use clean cloth (E120) dampened with

MEK (E244). Wear gloves (E184.1).

Do not flex fuel cell in repair area.

k.

Allow finished repair to set for 1 hour before

moving fuel cell.

l.

Allow finished repair to air cure for 24 hours

at room temperature of 70ºF (33ºC) minimum

before use.

INSPECT

FOLLOW-ON MAINTENANCE:

Visually inspect repair for workmanship, no loose

edges, no voids, cement fully cured.

END OF TASK

10-59