TM 55-1520-240-23-8

10-119

TEST PRESSURE REFUELING SYSTEM FOR LEAKS

(Continued)

10-119

d.

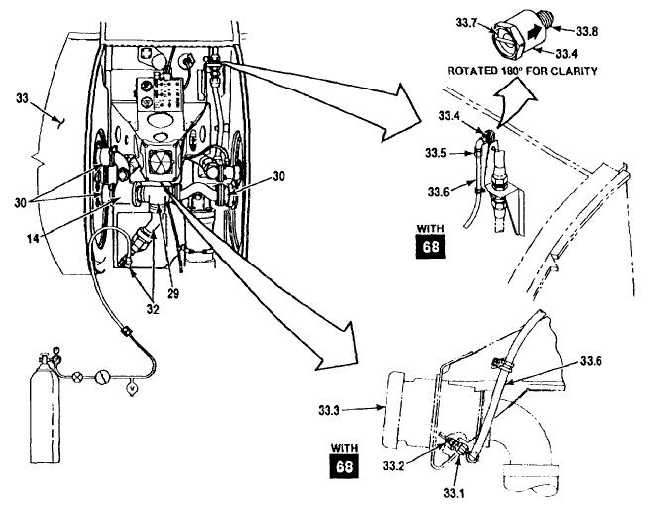

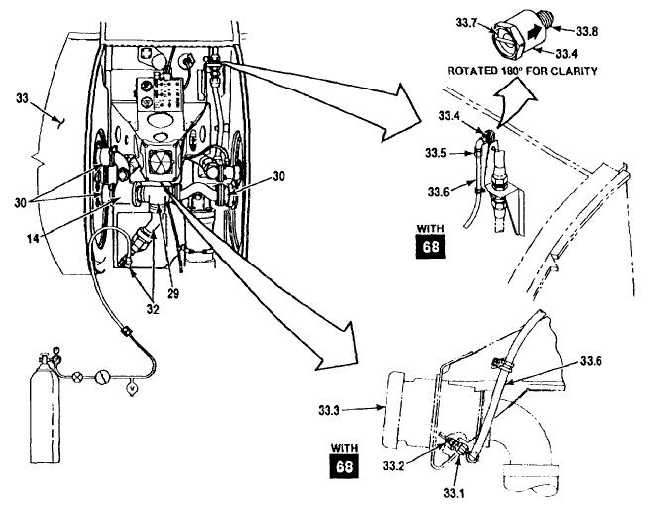

Check manifold (14), tee (29), breakaway

fittings (30), check valve (31), and elbows

(32) at forward end of main tank (33). Use

soap and water mixture as in step 17b.

e.

On aircraft with 68 do a check for leaks as

follows. Use soap and water mixture as in

step 17b.

(1)

Check vacuum relief hose fitting

(33.1) and nipple (33.2) on bottom of

refueling adapter (33.3). If a leak is

indicated, tighten or replace fitting or

nipple. Replace packing under nipple if

necessary.

(2)

Check vacuum relief valve (33.4) and

vacuum relief hose fitting (33.5). Tighten

fitting or replace line (33.6) if leakage

continues. Proceed as follows if nitrogen

is heard escaping from valve.

(a)

Remove pressure from system.

(b)

Remove vacuum relief valve (33.4)

(Task 10-87.3).

(c)

Blow low pressure air into screen end

(33.7) of relief valve to dislodge any

dirt that might be present inside.

(d)

Apply pressure (air or nitrogen) to

fitting end (33.8) of valve and make

sure valve holds pressure. If leakage

continues, flush valve with solvent

(E162), and perform step c again.

Replace valve if leakage continues.

(e)

Install vacuum relief valve (33.4) (Task

10-87.3), and continue leak check of

system.

10-515