TM 55-1520-240-23-8

10-50

INSTALL JET PUMP MOTIVE FLOW CHECK VALVE

(Continued)

10-50

Dry cleaning solvent (E162) is

flammable and toxic. It can irritate

skin and cause burns. Use only in

well-ventilated area, away from heat

and open flame. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

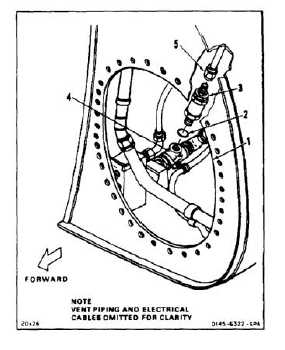

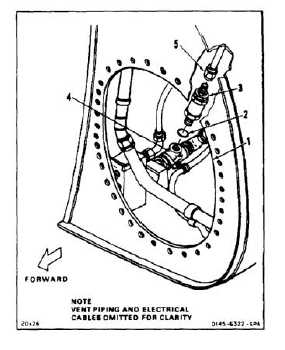

NOTE

Procedure is same to install motive

flow check valve in No. 1 or No. 2

main fuel tank. Installation of No. 1

(left) check valve is shown here.

1.

Remove barrier material and tape from access

hole in tank (1). Clean tape residue from tank.

Use dry cleaning solvent (E162) and clean cloths

(E120). Wear goggles to protect eyes. Wear

gloves (E186).

Do not puncture or scratch lining

of fuel tank. If lining is broken, fuel

penetrates and activates self-sealing

layers. Activated layers swell and trap

fuel. Activated green spongy material

also contaminates fuel system. This

makes it necessary to replace fuel

tank and flush fuel system.

2.

Install packing (2) and check valve (3) set in tee

(4).

3.

Connect hose (5).

INSPECT

FOLLOW-ON MAINTENANCE:

Perform vent system pressure test on affected tank

(Task 10-117).

Install main fuel tank forward access door (Task

10-52).

Test main fuel tank (Task 10-22).

Perform vent system flow test (Task 10-118).

Perform test of pressure refueling system (Task

10-119) and fuel feed system (Task 10-120).

Refuel helicopter (Task 1-51).

Bleed fuel system (Task 10-121).

Perform operational check of fuel system (left or right)

(TM 55-1520-240-T).

Inspect for leaks (Task 10-4).

Close forward landing gear access panel (Task 2-2).

END OF TASK

10-248