TM 55-1520-240-23-8

10-22

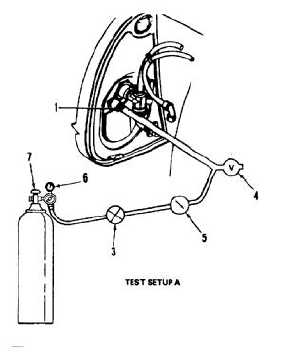

TEST MAIN FUEL TANK AFTER INSTALLATION

(Continued)

10-22

1.1.

Ensure nitrogen/air supply regulator output

pressure is 0 psi.

2.

Make sure valves (3 and 4) are closed. Connect

test setup to fitting (1). Open nitrogen/air supply

source and regulate pressure to 2 psi at tank

regulator (6).

3.

Open valve (3) and allow pressure to stabilize.

Structural damage to aircraft may

occur if more than 4.0 psi is applied.

3.1.

Increase pressure at regulator (6) and allow to

stabilize at 3.0 psi. Close valve (3).

4.

Wait 5 minutes. Check gage (5). If gage

indicates 2.5 psi or more, go to step 7.

5.

If gage (5) reads less than 2.5 psi, check test

setup connections at valves (3 and 4), and gage

(5). Use mixture of soap (E353) and water, and

brush (E85). Keep system under pressure for 15

minutes. If bubbles grow in size, connection is

leaking. Tighten connections or replace packings

as needed. Also check all joints, seams, and

cast components.

6.

Repeat steps 3 thru 4. If pressure is less than

2.5 psi, perform steps 7 and 8 and remove fuel

lines (Task 10-41). Check lines and connections.

Replace packing if needed. Install lines (Task

10-42). Repeat steps 3 thru 5.

7.

Shut off nitrogen/air supply (7). Open valve (4) to

reduce pressure to 0 psi. Close valve (4).

8.

Disconnect test setup from fitting (1). Cap fitting.

10-92