TM 55-1520-240-23-7

8-1

ENGINE INSTRUMENTS

(Continued)

8-1

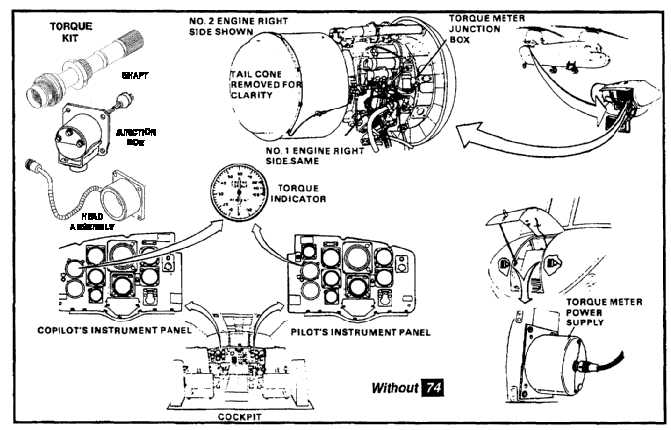

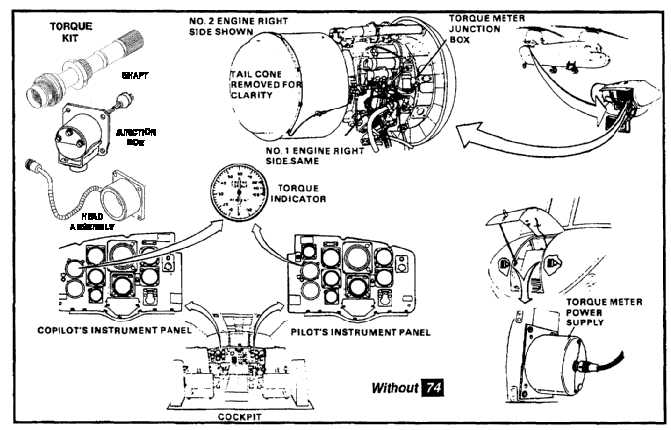

TORQUE INDICATING SYSTEM WITHOUT 74

Description

The torque indicating system, which monitors engine

power output, is a ratio system. It measures and

indicates the amount of engine torque. The system

consists of an engine-driven power shaft, a head

assembly and a junction box on each engine, a dual

torque indicator on each pilot’s instrument panel, and

two power supplies in the nose compartment.

NO BREAK - WORK HARDER

The head assembly and the power shaft make up a

transformer. The head assembly contains the single

primary and two secondary windings of the transformer.

The power shaft is the core of the transformer. The

junction box provides interconnection between system

components. The head assembly, power shaft, and

junction box make up a calibrated set. If one part is bad,

all three must be replaced with a matched set.

NO BREAK - WORK HARDER

A signal from the torquemeter power supply is applied

to the primary winding in the head assembly. With no

engine torque developed, equal signals are coupled

to the secondary windings. When engine torque is

developed, the power shaft is distorted, and unequal

signals are coupled to the secondaries. The signals

from the secondaries are rectified in the indicator and

moves the pointer to show percentage of rated torque.

NO BREAK - WORK HARDER

The indicator is calibrated 0 to 150 percent and has

two numbered pointers, one for each engine. Electrical

connections are provided through two connectors at the

rear of the clamp mounted indicators.

NO BREAK - WORK HARDER

The torquemeter power supply is a solid-state inverter

that converts dc voltage to ac voltage for use by the

engine torque sensor (head assembly).

8-10