TM 55-1520-240-23-7

8-26.1

REPLACE PITOT STATIC AND SIDESLIP SWAGELOK FITTINGS AND

TUBING

(Continued)

8-26.1

RECONNECT PREVIOUSLY SWAGED SWAGELOK

PARTS, PLUGS, AND FIRINGS

When installing nuts and plugs,

machined ferrule end of ports, or

reducing port connectors, tighten only

until index marks align, otherwise,

damage to tubing could occur.

4.

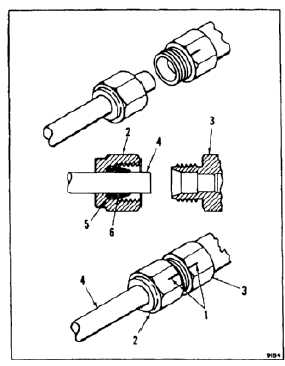

Check that ferrules (5 and 6) are in position in

compression nut (2).

5.

Insert serrated tube connector or non-corrugated

tubing (4) as applicable, into fitting (3) until ferrule

(6) seats in fitting.

6.

Tighten compression nut (2) finger-tight.

7.

Hold fitting (3) with wrench. Using another

wrench, turn compression nut (2) only until index

marks (1) align.

CONNECT FITTINGS THAT MUST BE SWAGED

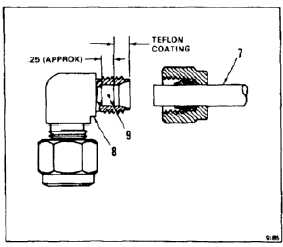

Do not apply adhesive (E50.1) to

Teflon coating.

NOTE

Perform steps 8 thru 12 when fittings

and tubing must be removed for

swaging. When fittings and tubing can

be swaged in their installed location

go to step 14.

8.

Remove end of tubing (7) from fitting (8).

9.

Check that end of tubing (7) and fitting (8) are

free from foreign material.

10.

Apply dab of adhesive (9) (E50.1) to inside of

fitting (8).

11.

Insert tube (7) into fitting (8) and hold in position

until adhesive sets. Wait at least one minute.

12.

Remove tube (7) and fitting (8) from their installed

location and swage.

8-93