TM 55-1520-240-23-6

7-258

TEST PRESSURE REDUCING VALVE (AVIM)

(Continued)

7-258

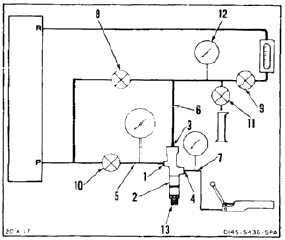

PRESSURE SETTING TEST

8.

Connect hoses (5, 6, and 7) to INLET port (1),

OUTLET port (3), and RETURN port (4) of valve

(2).

9.

Close shutoff valves (8, 9, and 10).

10.

Apply 100 psi pressure to RETURN port (4).

11.

Open shutoff valve (10) and apply 3,000 psi

pressure to INLET port (1).

12.

Adjust shutoff valve (11) for flow 20 cc per

minute from OUTLET port (3).

13.

Check pressure gage (12). Pressure shall be

1450 psi. If reading is not 1450 psi, adjust end

cap (13) to obtain reading.

14.

Close shutoff valve (11).

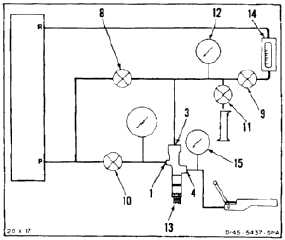

PRESSURE REDUCING AND FLOW TEST

15.

Adjust valve (9) for flow of 3.5 gpm on flowmeter

(14).

16.

Check pressure gage (12). Pressure gage shall

read 1230 psi or more. If pressure reading is not

1230 psi or more, adjust end cap (13) to obtain

reading.

17.

If end cap (13) is adjusted, repeat steps 9 thru

14. All pressure readings must be obtained at

one setting of end cap.

18.

Reduce pressure at return port (4) to 0 psi.

19.

Close valve (10) to reduce pressure at INLET

port (1) to 0 psi.

RELIEF CRACKING PRESSURE TEST

20.

Close shutoff valves (9 and 11).

21.

Open shutoff valve (8) slowly. Apply pressure to

outlet port (3) until cracking flow (rise in pressure)

at gage (15) is observed.

7-947