TM 55-1520-240-23-6

7-123

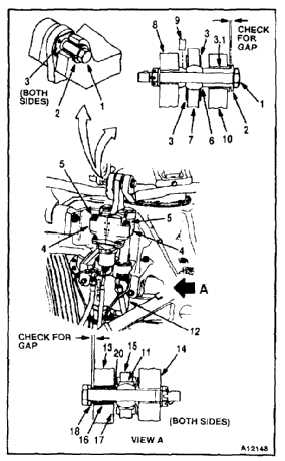

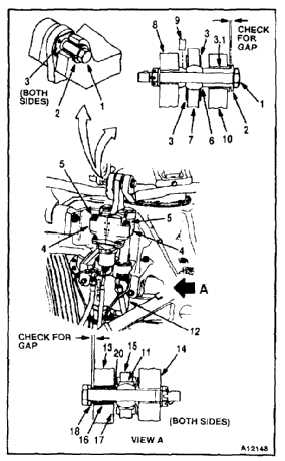

INSPECT PIVOTING AND SWIVELING SERVOCYLINDERS

(Continued)

7-123

NOTE

Procedure is similar to inspect forward

and aft pivoting and swiveling servo

cylinders. Forward pivoting servo

cylinder is shown here as typical.

Differences are noted in text.

1.

Check bolt (1), bushing (2), and plates (3) for

looseness. There shall be no loose bolt, bushing

or plates.

1.1.

Check that there is a gap between flanges of

bushings (2 and 3.1).

2.

Check valves (4). If either jam indicator (5) is

extended, reset and perform operational check

(TM 55-1520-240-T).

3.

Check bearing (6) for axial play as follows:

a.

Move lug (7) towards lug (8).

b.

Insert spacer (APP E-32) (9) between lug

(7) and lug (8). Spacer (9) must fit with no

looseness and must not be so tight that it

forces lugs apart.

c.

Move lug (7) towards lug (10).

d.

Measure distance between lug (8) and

spacer (9). Distance (axial play) shall not

exceed 0.010 inch.

4.

Check bearing (6) for radial play. Push lugs (8

and 10) down and then up. Feel for play between

lug (7) and lugs (8 and 10). There shall be no

play between lugs.

5.

Check bearings (11) for radial play. Push housing

(12) down, then up. Feel for play between lugs

(13 and 14) and lug (15). There shall be no play

between lugs.

6.

Check the following at the forward transmission

servo cylinder mounts.

a.

Check outboard pivoting servo cylinder lugs

(13). Bushings (16) shall not be past inboard

surface (17) of lug. If bushing is past surface,

replace forward transmission.

b.

Check for a positive gap between outer

surface of lug (13) and inside surface of

washer (18). If there is no gap present,

inspect hardware stack-up on the pivoting

servo cylinder or swiveling servo cylinder.

7-540