TM 55-1520-240-23-6

7-97

EXTENSIBLE LINK ACTUATOR CYLINDER FUNCTIONAL TEST (AVIM)

(Continued)

7-97

45.

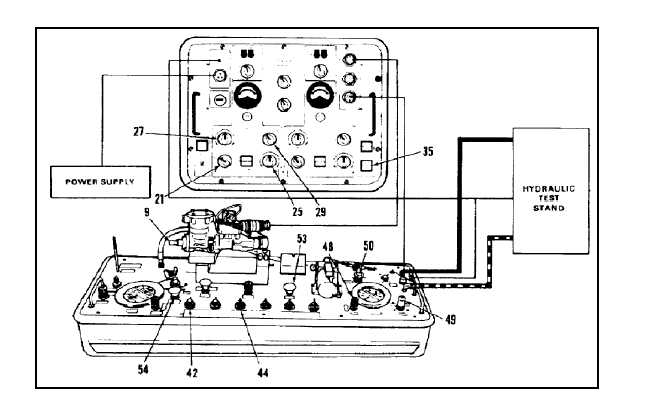

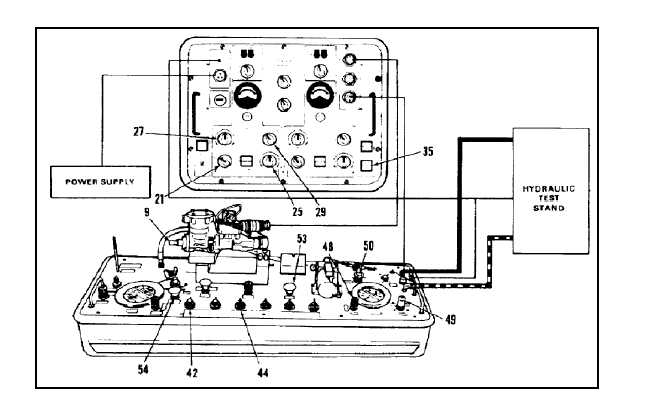

Slowly turn HIGH PRESS SHUTOFF valve (48)

to full OPEN.

46.

Turn VALVE CONTROL (25) from RETRACT,

then NULL, then EXTEND and then back to

NULL three times. There shall be no binding

of piston (9).

47.

Set FUNCTION SELECT switch (21) to SQ

WAVE.

48.

Turn SQ WAVE control (27) towards MAX until

piston (9) moves about 5/16 inch total stroke.

Allow piston to move for 15 minutes; then run for

50 strokes. Check for leaks at piston. Leaks

shall not exceed 1 drop in 50 strokes.

NOTE

Stroke rate can vary with temperature.

Count the strokes.

49.

Set FUNCTION SELECT switch (21) to

BALANCE. Set SQ WAVE control (27) to MIN.

Piston (9) shall stop.

50.

Allow piston (9) to sit for 5 minutes. Check for

leaks. There shall be no leaks.

51.

Set electrical and hydraulic unit controls as

follows:

a.

HIGH PRESS REGULATOR valve (49) to

DECREASE.

b.

HIGH PRESS SHUTOFF valve (48) to

CLOSE.

c.

SOLENOID SHUTOFF switch (35) to

CLOSED.

d.

SOLENOID valve (50) to CLOSED.

e.

AFCS PRESS SYS 1 valve (44) to VENT.

f.

Push and hold HIGH PRESS RELIEF valve

(53) and LOW PRESS RELIEF valve (54)

for 15 seconds.

g.

AFCS PRESS SYS 1 valve (44) to OFF.

h.

RETURN SYS 1 valve (42) to OFF.

52.

Set electrical unit controls as follows:

a.

LINK TEST switch (29) to VALVE.

b.

FUNCTION SELECT switch (21) to CLSD

LOOP.

53.

If no further testing is required, perform normal

shutdown (TM 55-4920-428-13).

END OF MANUAL CYCLING TEST

7-386